Optimization, data analysis, augmented reality

Knife systems

The heart of the chipper

The challenge

It is a continual challenge to improve the efficiency and productivity of wood processing operations. One specific challenge is to produce the highest volume of uniform wood chips – increasing accepts and reducing fiber losses – in a safe working environment.

The solution

ANDRITZ offers a range of chipping knife systems that help achieve high and uniform production with minimal losses. This range of knife systems ensures a solution that meets the specific requirements and layout of each plant’s chip processing operation.

TurnKnife systems

ANDRITZ TurnKnife systems increase the performance and efficiency of all types of chippers and sawmill chipping equipment. The TurnKnife system produces more high quality and uniform chips, with a higher accept fraction. Produced from the highest quality alloy chromium steel, the knives are specially treated to have a much longer edge life than conventional knives. The TurnKnife has a double-edge, making it reversible to eliminate knife grinding. The patented design ensures precise and consistent knife location to maximize chipping performance. The longer time between knife changes helps increase the chipping capacity. During operation, the TurnKnife stays sharper longer, which provides a better cut and minimizes small chip fractions (pin chip and fines). These factors ensure better downstream processes while saving money in the wood processing operation. Upgrading a chipper to the TurnKnife system improves chip quality and chipper performance with excellent economics.

TurnKnife features

- Improved safety and efficiency with light knives and no knife grinding

- Easy and fast knife changes

- One person knife changes from the front of the chipper

- Precise and consistent knife location

- Longer time between knife changes − increased availability

- Higher and more uniform chip quality

ANDRITZ offer TurnKnife systems for different applications: large disc chippers, drum chippers, rechippers after chip screens, or different sawmill chipping heads. All of these can be upgraded to the TurnKnife system.

TurnKnife systems

- TurnKnife System II (TK-II)

- TurnKnife System III (TK-III)

- TurnKnife System IV (TK-IV)

TurnKnife TK-IV is the latest knife system for all kinds of roundwood chipping. It combines a lightweight design with the power and strength to cope with all sorts of wood species. TK-IV has an excellent chipping geometry and extremely long running time between knife changes.

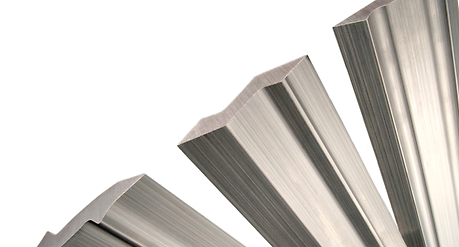

TurnKnives

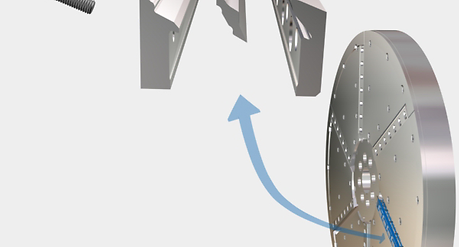

TurnKnife TK-IV cassette in a chipper disc

TurnKnife TK-IV cassette with knife protracted

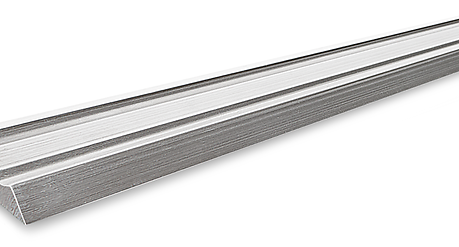

TurnKnife TK-IV knife

Supporting systems

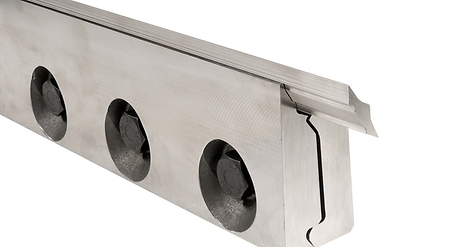

QuickClamp system

QuickClamp is a hydraulic clamping system for TurnKnife. The combination of QuickClamp and TurnKnife allows very fast knife changes and long running time between knife changes.

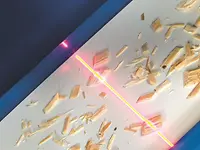

ScanChip

The ScanChip analyzer uses image analysis technology to monitor chip quality in a fast and accurate way. Different chip size distribution methods can be simulated and it also measures the chip dimensions (length, width, and thickness). ScanChip provides the information required to adjust a TurnKnife system in the chipper to produce optimal chip quality.

Automatic chip sampler

The automatic chip sampler is designed to collect representative samples from the chip flow and is mounted directly to the chip chute and it can be placed in optional positions in the mill. In ScanChip online version the analyzer is equipped with an automatic chip sampler and one or more return conveyors for returning the samples to the main chip flow, whereby the ScanChip provides an online chip quality measurement system. By using an automatic chip sampler a safe handling when collecting chip samples in the process is ensured.

PartnerChip full service contract

Close customer collaboration is a top priority for ANDRITZ. PartnerChip is a service program for knife systems. We provide the TurnKnife system plus the expertise of our specialists on a fixed-fee basis with the goal of helping you maintain the most efficient and profitable chip production possible. By including scheduled preventive maintenance, on-call 24-hour service, and technical support, you are assured safe and efficient production of your chipper.

Benefits of the PartnerChip contract

- Reliable TurnKnife system

- Scheduled service and on-call 24-hour service

- No inventory costs − no tied-up capital

- Technical support and chip quality optimization