Optimization, data analysis, augmented reality

Chipping systems

The heart of the woodroom

ANDRITZ has complete solutions for producing high chip quality with minimal wood loss.

The chipper: heart of the woodroom

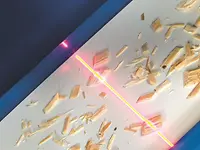

The chipper is the most important piece of equipment in the woodroom or woodyard because it has the potential to either produce high-quality chips or to destroy expensive raw materials.

Complete systems or specific equipment – ANDRITZ has the solution

ANDRITZ offers complete solutions for chipping that can be custom-configured to fit the layout and requirements of a specific wood processing application. The scope of supply can vary from complete plants to individual equipment delivery. ANDRITZ is very experienced in project management, ensuring deliveries that are on-time and on-budget, and produce excellent economic results for its customers.

The best chip quality at highest capacities

ANDRITZ offers a range of chipping systems that can meet the specific requirements and layout of a wood processing operation. There is a huge variation in incoming logs which has an effect on the chipping process. ANDRITZ has supplied over 1,100 chippers around the world and has built a depth of expertise.

As the leader in chipping technology today, ANDRITZ has delivered chipping systems that produce the highest chip quality at the largest throughput (world record is 500 m3 sub/every effective hour for a 20-hour period). High capacities are achieved by uniform, constant, and simultaneous chipping of several logs at the same time across the whole width of the bed knife.

By optimizing the cutting geometry, the cutting speed, and other parameters affecting the chipping process, ANDRITZ chippers are designed to produce very high quality chips at high capacity, even from small diameter wood.

The basic prerequisite for producing very high and uniform chip quality is that each log must be correctly oriented in relation to the chipper disc during chipping. Once the first knife hits the log, the log must not rotate during the chipping sequence and the log flow must be stable.