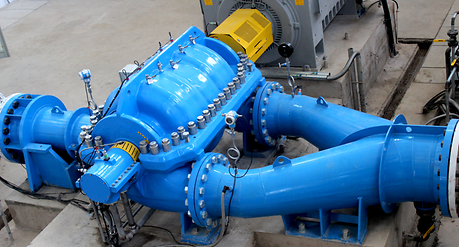

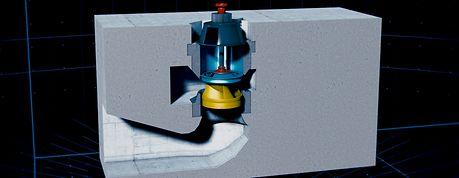

The ANDRITZ multi-stage axial split case pump from the ASPM series has a multi-stage impeller arrangement that can be combined in different ways to fulfill various application needs. This is a highly engineered pump designed to customers’ specific requirements and at the same time based on a modular design concept. In a horizontal installation, the motor can be placed on the left or right or on both sides as twin drive. For a vertical installation, ANDRITZ multi-stage split case pumps, ASPM series, are available in a radial split case design with barrel casing.

The machine is used for continuous pumping of clean liquids in water supply projects, power station projects and desalination plants. Peak efficiencies and user-friendliness make this technology particularly effective, and in the axial split design maintenance-friendly at high heads.

Thanks to the excellent efficiency, which is above the industry average, and the speed-variable drive (order-related), this pump is characterized by its low energy consumption. The design is rigid, the machine is calculated and designed to withstand all load cases which might occur during the lifetime of the pump. For more information on our multi-stage axial split case pump from the ASPM series please have a look at our brochures in the sidebar or contact us directly.