ANDRITZ AG, Austria

carbon steel processing

Eibesbrunnergasse 20

1120 Vienna

The compact rinse section pre-assembled in the workshop in Graz

Today, ANDRITZ pickling technology prevails on the world market as a synonym for high productivity, low investment costs, and highest production flexibility.

Continuous pickling lines (CPL) in the design well-known today with shallow-tank, high-turbulence pickling were defined widely and decisively by ANDRITZ-RUTHNER.

As a pioneer in the design and manufacture of polypropylene pickling tanks, ANDRITZ redefined shallow-tank and turbulent pickling. Many years of experience worldwide in revamping, processing, and full turnkey supply of continuous pickling lines – also as a part of pickling line and tandem cold mills (PLTCM) – form the basis of our customers’ satisfaction, which is our top priority. The optimized pickling process with individual circulation and heating system ensures minimized consumption of utilities, while the result is always a scale-free strip surface. These processing lines are designed to process strip thicknesses from 0.8 mm up to 6.5 mm and strip widths from 600 mm up to 2100 mm in different steel grades. We have supplied lines for carbon steel with a maximum capacity of up to 1,700,000 tons/year and pickling speeds of 400 meters/minute.

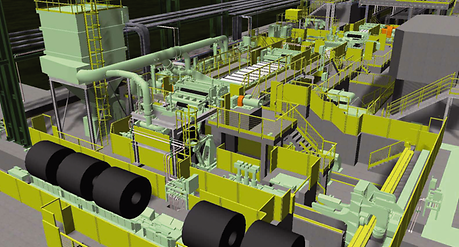

3D model of the entry section in a continuous pickling line

Mathematical optimization models for essential modules