ANDRITZ Metals France S.A.S.

Carbon steel strip processing furnaces

ANDRITZ Metals offers a wide range of well-proven technologies to provide the required process for a large range of steel grades – from commercial quality to high-strength steels (HSS), advanced high-strength steels (AHSS) such as dual phase, Complex Phase and Quench & Partitioning steels, with different types of coating suitable for GI (galvanized), GA (galvannealed), GL (“galvalume”), Zinc-Magnesium, AlSi, and other products.

In addition to the process requirements, we focus both on minimizing energy consumption, environmental impact, as well as on optimizing transition times based on thermodynamic mathematical models and on design to suit all maintenance aspects.

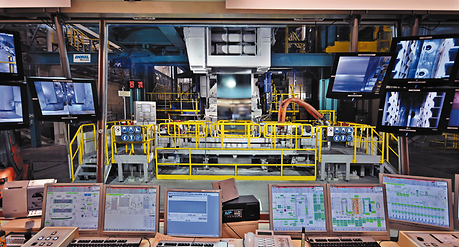

Voestalpine Stahl, continuous galvanizing line FVZ4

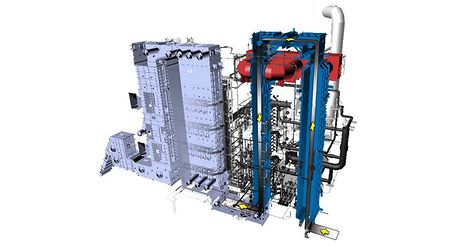

The ANDRITZ Direct Fired Furnace (DFF) to heat the strip up to 680-750° C with its preheating pass (using its own waste gases) replaces up to 12 passes with radiant tube heating in a vertical furnace. ANDRITZ Selas burners allow very homogeneous and accurate temperature regulation. A precise control of oxidation/reduction can be achieved for either strip cleaning, eliminating oil and iron fines, or preparation of High Strength Steel to get good adherence during galvanizing or galvannealing process.

Some Direct Fired Furnace References:

| Customer: | Start-up: | Product: |

| ArcelorMittal, USA | 1991 | Auto / AHSS |

| Voestalpine, Austria | 2003 | Auto |

| Tata Steel, UK | 1991, 2004, 2017 | Auto / DP |

| Voestalpine, Austria | 2007 | Auto / AHSS |

| Voestalpine, Austria | 2010 | Auto / AHSS |

| Baosteel, China | 2015 | Auto / AHSS |

| ArcelorMittal, Belgium | 2016 | Auto / GEN3 |

| ArcelorMittal, Belgium | 2018 | Auto / GEN3 |

| ArcelorMittal, France | 2019 | Auto / PHS |

Customer benefits:

Radiant tube heating (RTH) to reach the annealing temperature up to 900-920° C, with ON/OFF recuperative or regenerative burners for I, U, W, P and PP thin radiant tubes

Induction heating with different applications, used as a simple temperature boosting device in an air or furnace atmosphere of H2 and N2, which requires specific, patented technology to protect the coil from the atmosphere.

Electrical elements, such as wires, strips, or radiant tubes adapted to the process.

Voestalpine Stahl, continuous galvanizing line FVZ4

A wide range of different designs are available to suit the process requirements to an optimum :

Using higher H2 concentration allows even much higher cooling rates, without safety issues (in accordance with ATEX regulation).

After-pot jet cooling for different types of coating and for best strip stability.

A chamber which can operate either in cooling mode or soaking mode without losing strip temperature

All ANDRITZ line models