ANDRITZ detrashing systems

The FibreSolve FSR pulper is typically kept in good running order by using a detrashing system. The system cleans a continuously operating pulper and separates fibers from the impurities. A partial flow of approx. 20–30%, including most of the accumulated contaminants, is handled in this detrashing process.

The ANDRITZ detrashing system consists of either a TrashWell TW with grapple hoist for heavy reject removal or a TrashTrap TT equipped with a heavy junk trap.

The FibreGuard FG detrashing system comprises a continuous FibreGuard FG detrashing machine which is fed by the detrashing pump DP.

The combination of these components into one smooth detrashing process results in minimum debris content in the pulper vat and includes the separation of heavy and light debris.

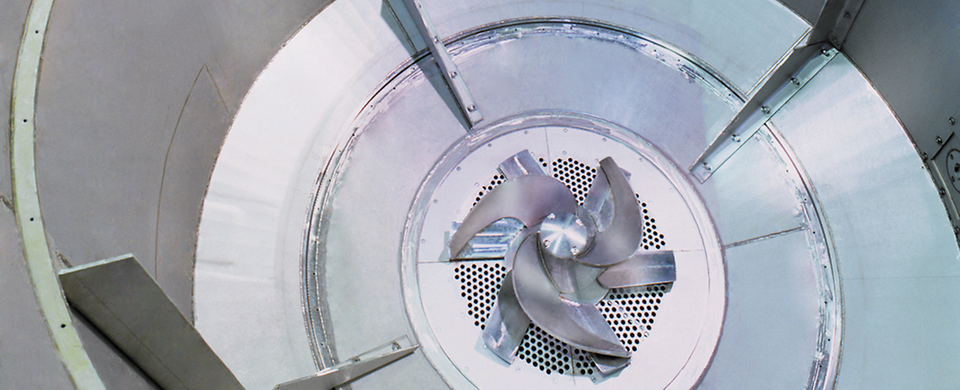

Features of FibreGuard FG detrashing machine

- Space-saving hinged cover

- Waterless shaft seal

- Pulper discharge flows to the detrashing machine with (FibreGuard FG) additional pump

- Easy rotor assembly with shrink fit on a straight shaft

- Capacity increase through forward feed of detrashing machine accepts

- Wear resistant rotor saves operating costs

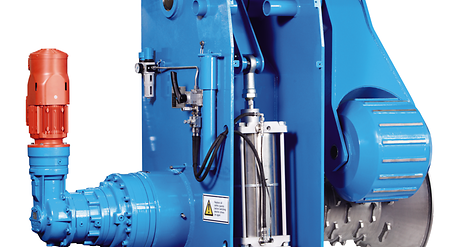

Features of the detrashing pump DP

The detrashing pump is part of the FibreGuard FG system for transferring pulp from the pulper vat to the detrashing machine. It is designed for trouble-free operation and is highly efficient, resulting in low wear, long life, and low energy consumption.