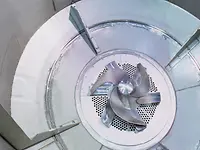

HC pulper FibreSolve FSH: efficient pulping for various pulp grades

The FibreSolve FSH pulper is operated in batch mode. The outstanding design of the FSH rotor provides high capacity, small vat volumes, and low power consumption. The unique rotor creates excellent circulation within the vat which permits operation at consistencies up to 18%. Guiding plates on the rotor flights support the pulp flow. The FibreSolve FSH is suitable for all waste paper grades, including wet strength material. Additionally, it can be used for virgin fiber and broke applications. Optional screen plates and deflaking blocks offer highest efficiency and flexibility. Depending on the amount of coarse contaminants in the raw material, two different discharge systems are applied:

- FibreGuard FG-HR system with the FibreWash drum FWD

- FibreGuard FG-H system