Concentrated performance in a very compact design

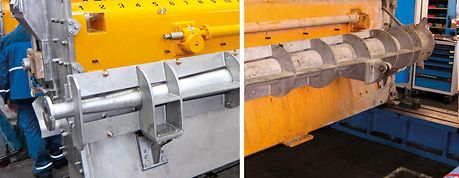

The newly developed LC refiner combines the well-proven basic principles of the current ANDRITZ TwinFlo refiner with the higher energy input possible, reduced maintenance needs, and increased refiner plate lifetime.

The ANDRITZ TwinFlo Prime features the following innovations:

- Fixed connection between rotor and shaft

- Hydrodynamic, water-lubricated plain bearing

- Reduced wear on refiner plates

- Advanced operating conditions