Find the right products for your needs from ANDRITZ Feed and Biofuel

Conditioners

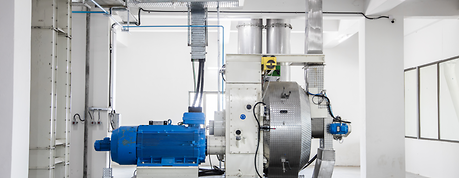

ANDRITZ offers four different series of conditioners that ensures optimum preparation of the material before the pelleting or extrusion process.

Correct conditioning of a material is necessary in order to obtain a good pellet quality and an effective utilization of the pelleting or extrusion installation. Optimum conditioning results in the desired activation of natural binders by using heat, moisture, and time. The ANDRITZ range of conditioners comprises single or dual conditioning.

Conditioner – type CM

The CM conditioner ensures excellent mixing and optimum retention time.

Key features:

- Provides uniform feeding to the pellet mill or extruder

- Clean design and stainless steel construction

- Easy inspection and cleaning

- Wide paddles that are individually adjustable

- Controlled steam and liquid addition

Conditioner – type CRT

The CRT conditioner ensures uniform product, good absorption, few blockage, and smooth running.

Key features:

- Material flow – first-in first our principle

- Conditioning at temperatures up to 95 ⁰C

- Formatting to eliminate common salmonella strains and similar bacteria

- Pasteurization to provide sufficient time to ensure uniform distribution of heat

- Time for steam and other liquids to be absorbed – typically operating at 2-4 minutes

Conditioner – type CM-PH

Experience has shown that it is quite a challenge to reach a temperature of 84 °C in the first batch and ensure pasteurization of the material. With the CM-PH series it is possible to reach at least 84 °C in the first production batch, ensuring that the material will be as hygienic as possible.

Key features:

- Closeable inlets and outlets

- Easy inspection and cleaning

- Wide paddles that are individually adjustable