Fast, easy and trouble-free installation for a 10TPH feed plant.

Animal feed processing

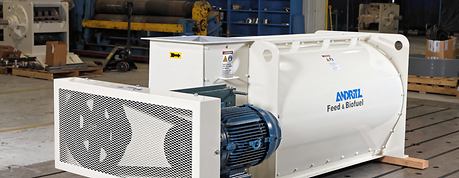

ANDRITZ designs and manufactures all key processing machines and offers complete feed pelleting plant solutions to the global animal feed and livestock industry.

Want to learn more about the pelleting process?

Download our Feed Manufacturing Handbook for Animal Feed.

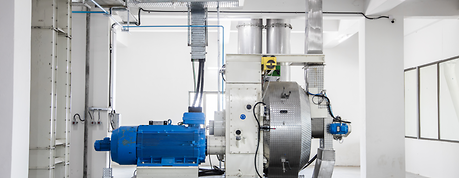

ANDRITZ equipment for feed pelleting

Our feed processing technologies are available in various models and with optional accessories to offer the optimum solution for your specific production needs.