ECO-FRIENDLINESS

Sustainable wood sources and production process is more environmentally friendly compared to traditional methods, like viscose.

Perfect combination of environmental sustainability, comfort, moisture management, and versatility, that is what Man Made Cellulosic Fibers, namely Lyocell, make to one of the most promising markets. The perfect combination of environmental sustainability, comfort, moisture management, and versatility—this is what makes artificial cellulose fibers, namely Lyocell, one of the most promising fibers for sustainable, high-quality textile and nonwoven products. Textiles made of Lyocell have a smooth and cool feel with a flowing drape, are less likely to wrinkle, and can be washed and dry cleaned.

ANDRITZ MMCF (Man Made Cellulosic Fiber) technology represents a comprehensive, next‑generation solution for producing sustainable cellulosic fibers such as Lyocell. Designed to meet the growing global demand for eco‑friendly textile materials, ANDRITZ provides complete MMCF production systems—from engineering and pulp preparation to specialized equipment like flash dryers—leveraging decades of expertise in pulp and paper processing.

ECO-FRIENDLINESS

Sustainable wood sources and production process is more environmentally friendly compared to traditional methods, like viscose.

BIODEGRADABILITY

Due to their origin (wood), the fibers are biodegradable and contributing to reduce environmental impact.

HIGH MARKET DEMAND

Lyocell production volumes are expected to grow from 1,200 kt in 2025 to around 2,000 – 2,500 Kt in 2030.

MOISTURE ABSORPTION

Excellent moisture absorption properties, making them ideal for activewear and clothing worn in hot climates.

VERSATILITY

Fibers can be blended with other fibers like cotton, wool, or polyester to enhance their properties, making them versatile for various textile and nonwoven applications.

SOFTNESS AND BREATHABILITY

Renowned for their softness, often compared to silk. This makes them comfortable to wear. In addition, the fibers have a natural breathability, allowing air to circulate.

ANDRITZ brings decades of expertise from the pulp and paper industry, giving the company a unique advantage in dissolving pulp technologies, mechanical textile recycling, and nonwoven processes. The integration of MMCF and Lyocell solutions fits logically into the existing ANDRITZ portfolio, supported by deep know‑how in both dissolving pulp production and nonwoven manufacturing. With global Lyocell production expected to grow significantly due to rising demand for sustainable textiles, ANDRITZ is receiving clear signals from the market and strong requests from pulp producers to expand in this field. To strengthen its competence even further, ANDRITZ acquired SciTech‑Service Oy in July 2023, adding specialized MMCF expertise and an experienced team that now actively drives ANDRITZ’s development work in Lyocell and related areas. This initiative supports the company’s strategic goal of accelerating the transition toward more sustainable textile and fiber‑based products.

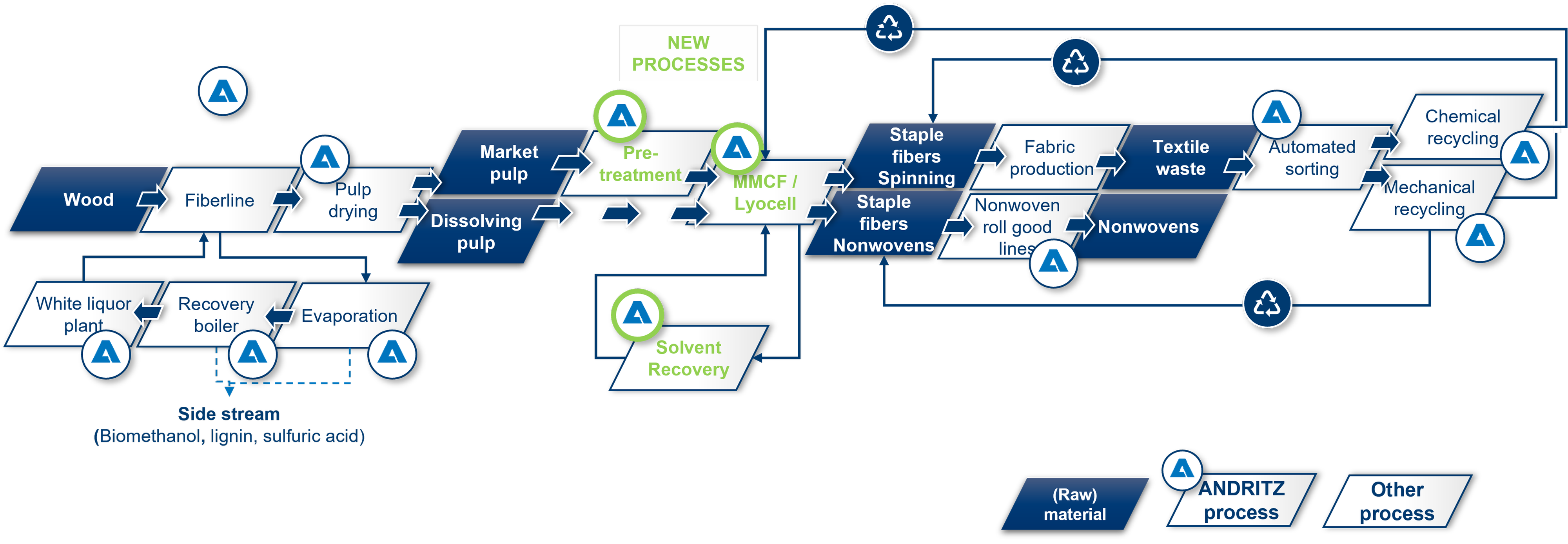

ANDRITZ transforms renewable wood into sustainable textile fibers through an integrated, end‑to‑end process. It begins with the production of high‑purity dissolving pulp, where wood chips are cooked, purified, and processed into cellulose tailored for fiber applications. This pulp then enters the Lyocell/MMCF solution preparation stage, where the cellulose is dissolved in a low‑toxicity organic solvent to create a stable spinning dope. Using high‑precision ANDRITZ spinning and fiber‑forming technologies, the solution is extruded through spinnerets into a controlled environment where the cellulose regenerates into continuous filaments. These filaments are washed, dried, and cut into staple fibers or further processed depending on customer needs. Advanced ANDRITZ automation and Metris digitalization ensure quality, traceability, and efficient resource use throughout the entire line. The result is a high‑performance, biodegradable fiber produced from wood, a fully integrated, future‑ready solution supporting the textile industry’s transition to more sustainable materials.

Man Made Cellulosic Fiber process: A homestand for ANDRITZ

Man‑made cellulosic fibers (MMCFs), including Lyocell, are increasingly positioned as strategic materials for the nonwoven and the textile industry as it shifts away from fossil‑based polymers. Studies show that the nonwoven sector is undergoing rapid transformation driven by sustainability demands and regulatory pressure, particularly regarding microplastics and circularity requirements. Lyocell stands out due to its high mechanical strength, biodegradability, and lower environmental footprint compared to conventional synthetic fibers such as polypropylene (PP) and polyester (PES).

Lyocell fibers, produced through a closed‑loop solvent process (non-toxic solvent) from wood‑based cellulose, combine performance with sustainability. Research on Lyocell-based nonwovens highlights:

Lyocell is made for both worlds: high-quality textile products and various nonwovens

STANDARD LYOCELL PLANT:

Optimized of CAPEX and OPEX, 10,000 – 100,000 tpy capacity

RESEARCH & DEVELOPMENT:

Several lab and pilot facilities; cooperation with leading universities in Finland and Germany

TAILOR-MADE SOLUTIONS:

Engaging with partners, customers for joint-development initiatives to design advanced solutions

SERVICE:

Consultancy, feasibility studies, process audit, retrofit/de-bottlenecking, automatization & digitalization

INTEGRATION WITH NONWOVEN:

Offering to customer integrated solutions of MMCF with nonwoven lines

RAW MATERIAL FLEXIBILITY:

Different raw material to optimize the cost and differentiate in product quality – from proteins to different types of cellulosic material (pre-treated pulps, dissolving pulps, textile recycled, etc.)

DIGITALIZATION – METRIS AI:

Increase of automation level to optimize labor costs; Implementation of METRIS solution

NEXTGEN MMCF SOLUTION:

Offering to customer advanced IL (Ionic Liquid) solution to produce textile fibers