ANDRITZ vertical volute pumps from the CVP and VVP series operate in a wide range of industrial applications. In the water sector, they function as water transport pumps for irrigation, drainage, and flood control as well as water supply pumps for drinking and industrial water suppliers. Additionally, they can be used as cooling water pumps for thermal power stations and as seawater intake pumps for desalination plants.

Thus, these pumps can transport many different media. The pumps must have various properties, depending on the medium concerned. That is why the choice of material and suitable finishing are the determining factors for functioning and stability of the pump. Different materials are used depending on the service conditions and customer requirements: cast iron, cast steel, non-alloyed and low-alloyed steel grades, stainless CrNi steel grades, duplex and super duplex steel grades.

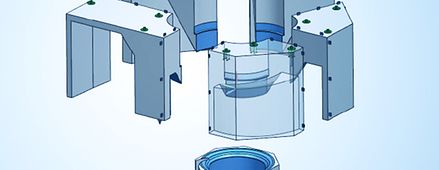

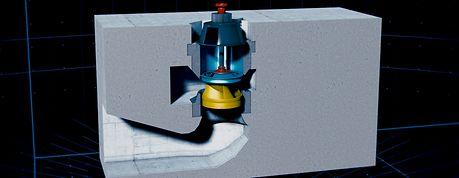

Similarly, the hydraulic dimensioning and design of the volute casing depends on the specific output characteristics. Optimum flow is achieved in the volute thanks to its individual shaping, thus also achieving a high level of efficiency. The volute casing is manufactured as a concrete or metal volute. The metal volute is a welded structure consisting of several segments and can be embedded in concrete as an option. This design is used primarily for larger delivery heads if a solution with a concrete volute is no longer feasible due to strength requirements. From the technological and economic points of view, concrete volute pumps are the best solution when large amounts of water are to be delivered. The concrete casing has a long service life and is resistant to erosion as well as to both seawater and brackish water. Furthermore, the material costs are low.

For more information on our vertical volute pumps from the CVP and VVP series please have a look at our brochures in the sidebar or contact us directly.