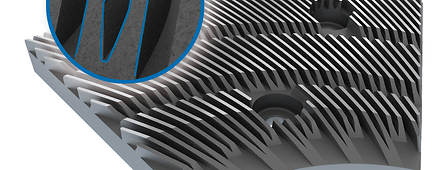

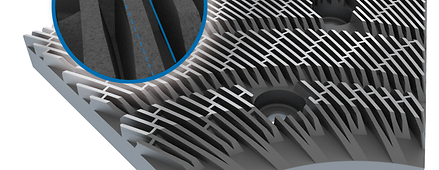

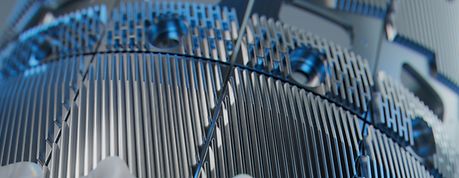

Spiral bars

To ensure consistently high quality in the processing of fiber material, any form of process variability should be minimized. Research shows that bar angle significantly influences refining results. Yet the crossing angle of parallel bar plates varies significantly. So we asked ourselves, "Can the shape of the bars be optimized to provide more homogeneous fiber treatments?"