Optimization, data analysis, augmented reality

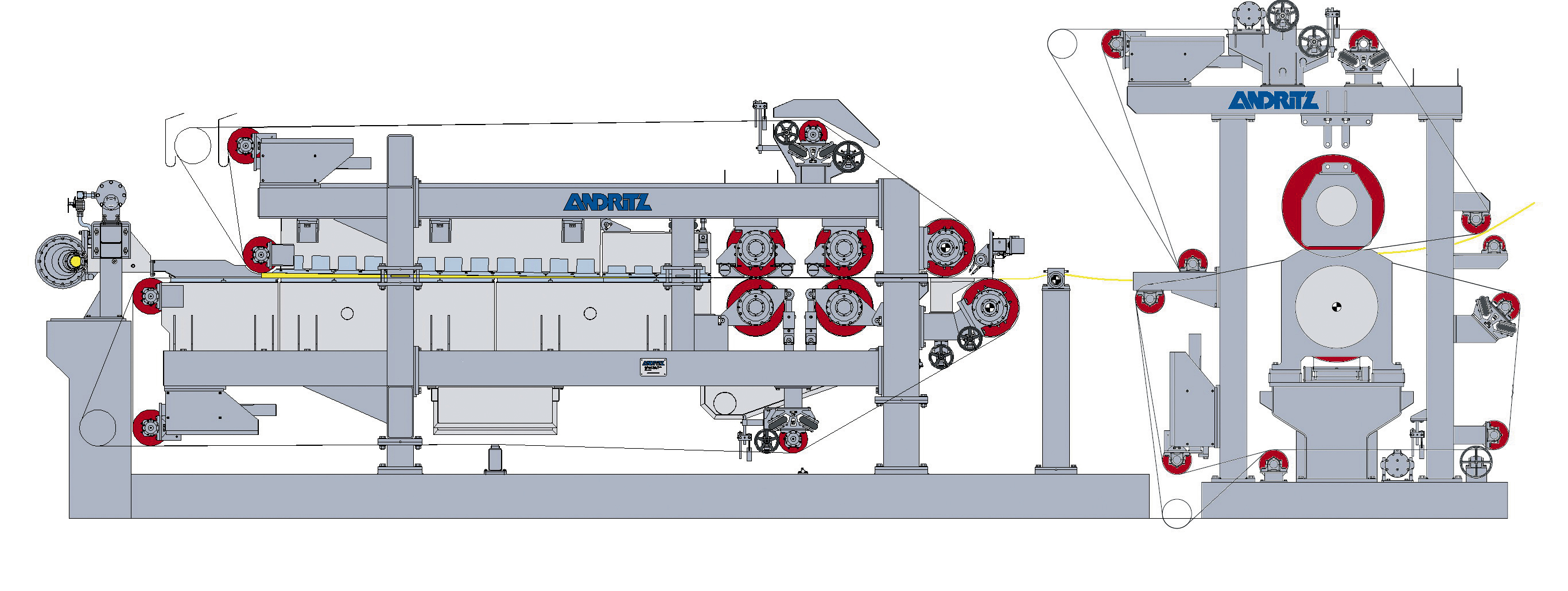

ANDRITZ pulp dewatering machines for fluff pulp applications

ANDRITZ Twin Wire machines achieve proper sheet formation, high dryness, and high specific production at minimum operating and maintenance costs.

ANDRITZ pulp dewatering technology ensures high performance and safe operation of market fluff pulp sheet drying plants.

ANDRITZ headbox for fluff pulp dewatering machine

Fluff pulp is mainly used for hygiene products. The main difference to standard market pulp is the density (bulk) of the sheet after drying. For such products, the density is between 0.4–0.65 kg/cm³ (bulk from 1.54–2.5 cm³/kg). The pulp product is usually stored on reels for further fluffing in a hammer mill. High fluff quality (small amount of knots) can only be achieved with proper sheet formation and the right density.

ANDRITZ fluff pulp dewatering machines for optimum sheet quality, fiber formation, and tensile strength

ANDRITZ is a pioneer in Twin Wire dewatering. The ANDRITZ Twin Wire pulp machine for market fluff pulp dewatering is a well-proven technology and delivers high-quality sheet and fiber formation.

Components of ANDRITZ market fluff pulp dewatering machine

- Headbox

- Former

- Press section with heavy duty press, shoe press

Advantages at a glance

- Up to 50% dryness without vacuum

- Low operating and maintenance costs

- Low energy consumption

- High plant availability

- Optimum sheet formation

ANDRITZ fluff pulp dewatering machine

ANDRITZ headbox – optimum sheet profile and sheet formation

Well-proven, state-of-the-art headbox technology is used in paper production as well as for fluff pulp dewatering machines. The hydraulic flow is even and uniform due to the conical inlet header. In combination with the step diffuser, this delivers a proper sheet profile and a strong sheet.

Advantages of the ANDRITZ headbox

- Conical shape for even hydraulic flow and homogenous pulp distribution

- Dilution profiling system (manual or automatic control) in turbulence section for optimum sheet profiles

- Proper sheet formation and high sheet strength

- Easy maintenance (swiveling type, good accessibility)

Advantages of the ANDRITZ former

- Double-sided dewatering

- High capacities

- Gentle and efficient dewatering

- No vacuum applied

- Potential energy reduction of 10–20 kWh/t compared to conventional Fourdrinier machines

- No risk of sheet sealing

- Fines are distributed evenly in the sheet

- Proper formation

- Heavy sheet due to high basis weight – easy to cut

- Easy operation and high up-time

- Minimized maintenance due to simplified design

Advantages of the ANDRITZ heavy duty press

- Fully cantilevered frames, minimal felt change time

- No need to remove felt guide rolls for felt change

- Can use heavy felts with high water retention capacity

- All felts run above machine floor, clean operation on ground level

- All felts designed for the same length

- Large diameter press rolls (wide press nip)

Advantages of the ANDRITZ shoe press with X-Nip (ANDRITZ PrimePress X)

- 3–5% higher dryness than HI presses

- Highest dryness due to optimum pressure curve

- Long life of press sleeves