Optimization, data analysis, augmented reality

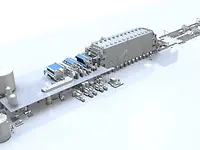

Screening, cleaning, and machine approach technology for pulp sheet drying plants

ANDRITZ pulp screening and pulp cleaning systems achieve excellent pulp cleanliness and maximum yield at minimum operating and maintenance costs.

ANDRITZ Bar-Tec scrren basket

Pulp screening, cleaning, and machine approach process

The feed for the screening plant comes from the blend chest. Pulp from the blend chest is mixed with dilution water to achieve the required consistency. Accept from screening and cleaning are collected in the machine chest.

ANDRITZ’s pulp screening, cleaning, and pulp machine approach technologies achieve a very homogenous pulp flow and ensure stable and safe operation in market pulp sheet drying plants.

Dolphin rotors for improved screening capacity with less energy

Special features of ANDRITZ pulp screening and cleaning for market pulp

- Multi-stage system for highest efficiency and lowest fiber losses

- Slotted screen baskets

- Efficient junk removal in first stage

- Heavy and lightweight impurities removed

- Efficient de-aeration of pulp suspension

- Highest efficiency due to generously sized screens and optimum slot passing speed

- Less wear because of low slot passing speed in screens and efficient sand removal in cleaners

- Specially designed screen bars with optimized profile in order to obtain highest efficiency and production

- Each screen is equipped with chromium-plated baskets for high wear resistance

- Solid machine design

- Closed system

- Minimum space requirements