Jari Keränen

Sales Director

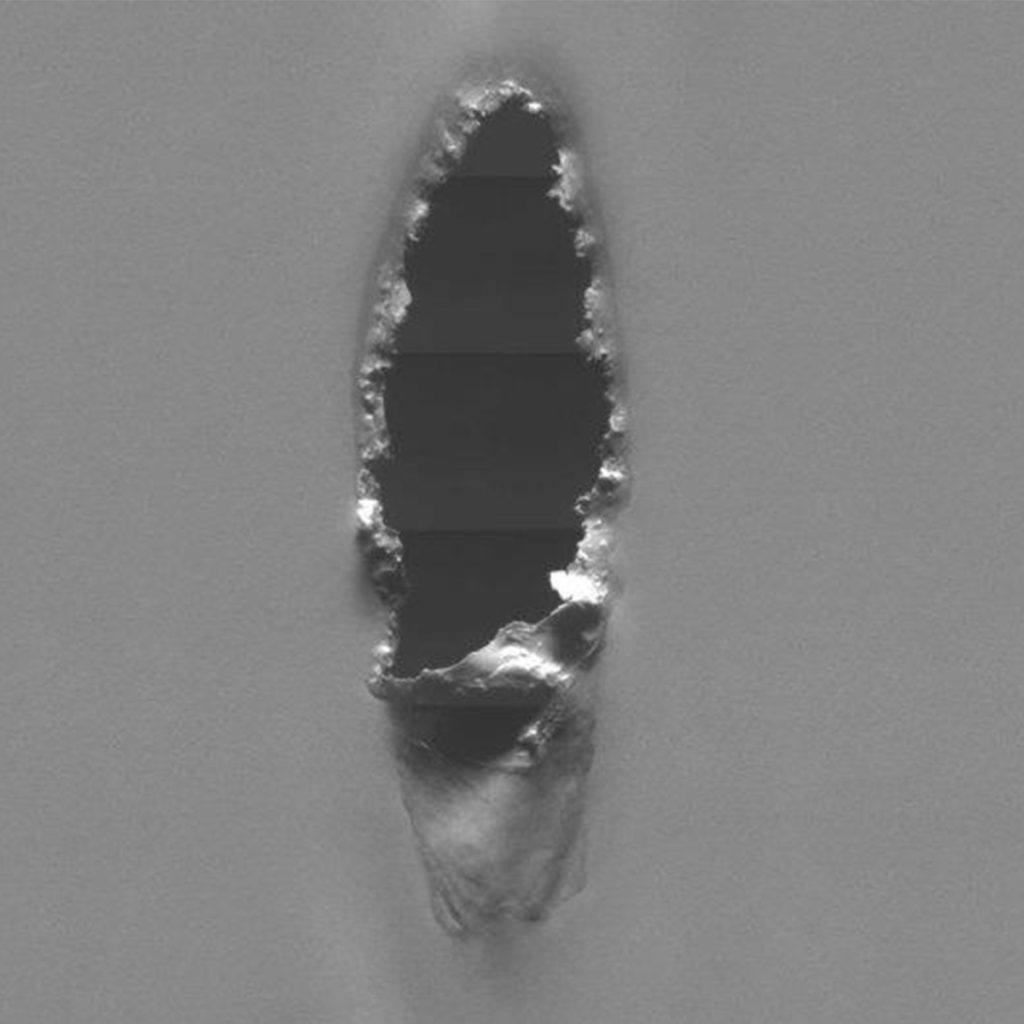

Procemex Paper Web Inspection System provides continuous detection of all paper defects. Web Inspection camera system can be seamlessly integrated to Procemex Paper Web Monitoring System.

The world leading Web Inspection technology enables highest level defect detection with Photographic Imaging Quality.

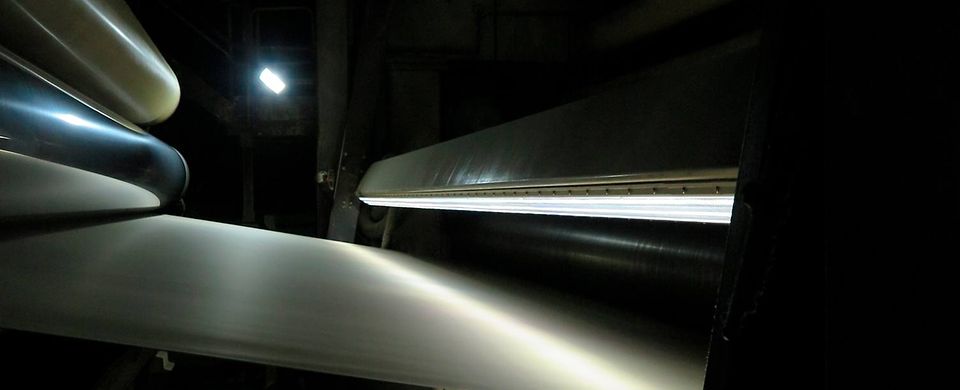

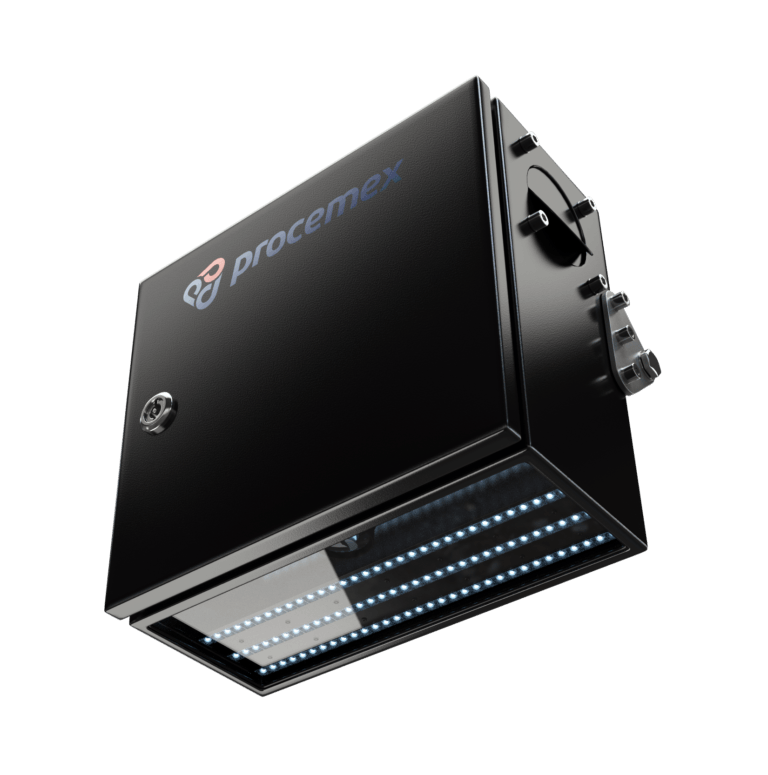

Powerful strobing LED lighting eliminate blur and produce photographic image

quality.

The applications range today from coated box board to coated paper, magazine paper, newsprint, tissue and liner board. In addition, utilization of auto-shutter of a smart camera design is preferred amongst specialty paper makers for its wide range of detection capabilities.

Pre-classification inside Procemex Smart Camera allows instantaneous paper quality classification for first level defects.

Multi-frame camera imaging providing higher quality images to the classification engine and increasing accuracy over antiquated line-scan technology.

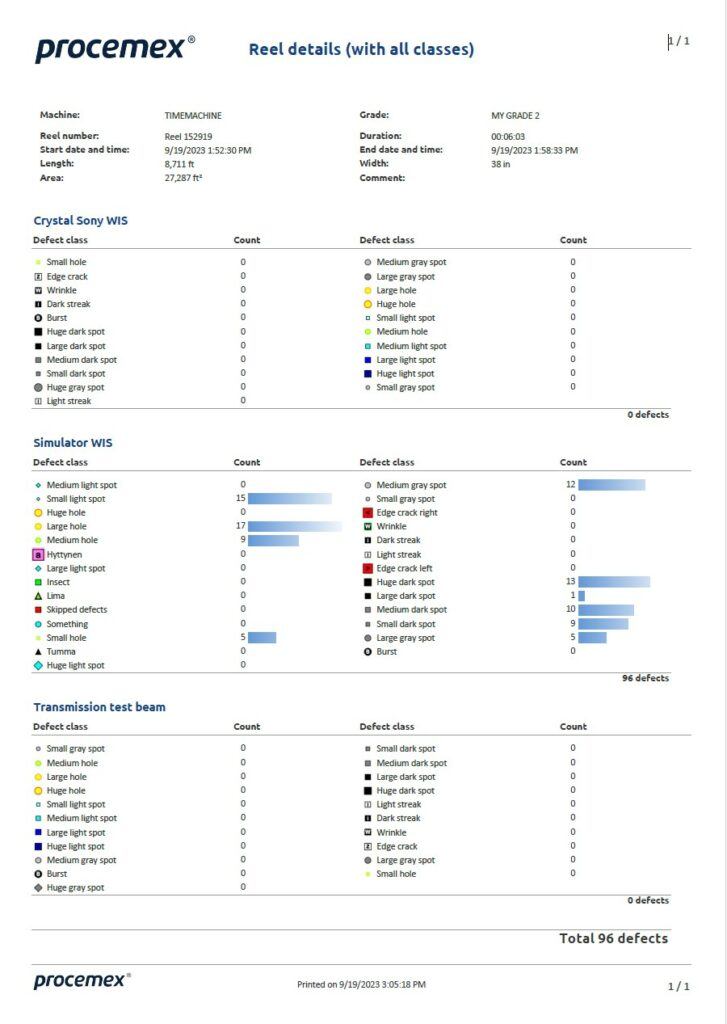

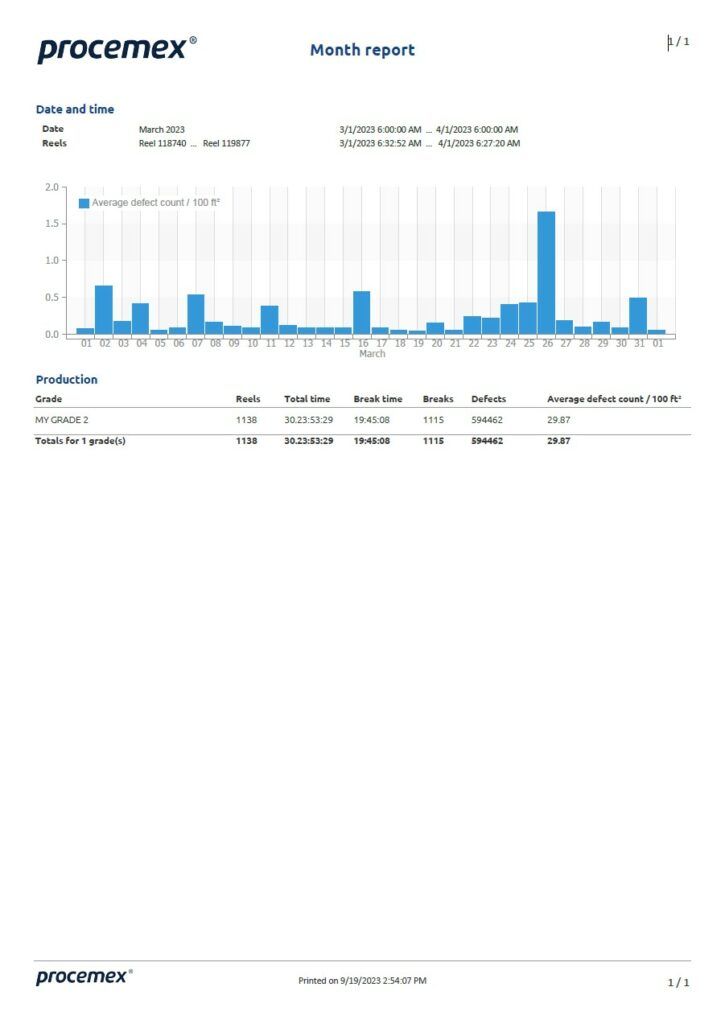

Create customized, well visualized, and easily exportable web inspection and monitoring reports that empower you to make informed decisions, improve product quality, and streamline your production processes. The Procemex Reporting Engine is a web browser-based tool, that provides both easy and secure access without the need for external software installation. As an integral part of the Procemex Web Monitoring and Inspection System, this reporting tool empowers mill operators and production managers to effortlessly generate insightful reports that provide invaluable insights into your production process.

Procemex smart camera activates one or more light frame LED flash profiles and illuminates only during camera image exposure.

Procemex Flex camera fully and automatically controls the strobe lighting to match the camera frame rate, with camera shutter speeds automatically controlling each light pulse length. This means the strobe light is illuminated when the camera is filming. This strobe lighting uses just an average of 30 W compared to 400-500 W (standard metal halide light), thus eliminating heat and energy consumption problems. Strobe lighting and new super light sensitive CMOS sensor technology, results in camera exposure times of 5-20 Microseconds freezing paper movement effectively, and producing crystal clear images.

Utilization of a strobed light technology allows a long life of LED by elimination of heat generation

Running winder with optimum efficiency requires automatic defect finding in the process.

Running winder with optimum efficiency requires that winder operators know paper defects locations in advance. Based on accurate knowledge of the machine directional and cross directional defect location, operators can make educated decisions whether to keep full speed, slow down, crawl or stop the winder for patching the defect. This process can be also be automatic.

Rolls can be run again after winder at re-reeler in case it is necessary to remove defects and save rolls. As the bar code is at that phase already removed, it is necessary to crawl the roll to the first defect and let the system synchronize the rest of the defects automatically.

Automatic Winder Target Control Features

Procemex Web Inspection Camera System includes a number of features that help paper machine operators in their work.

Many features that help paper machine operators in their work

To better understand how our Web Inspection system recognizes and analyzes defects on your paper, we encourage you to send us a paper defect sample for analysis.

Our experienced testing team will conduct a comprehensive WIS analysis once your samples arrive, providing you with valuable insights that will help you assess the suitability of our solutions in your mill’s unique production environment.