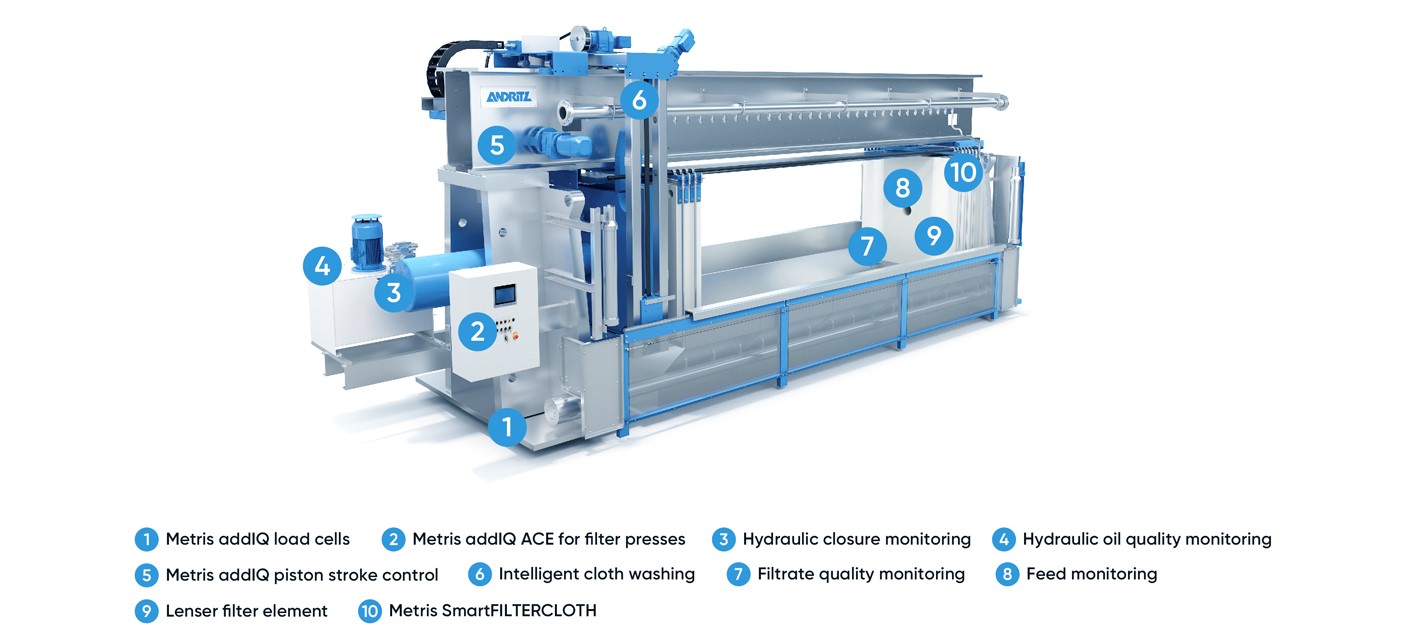

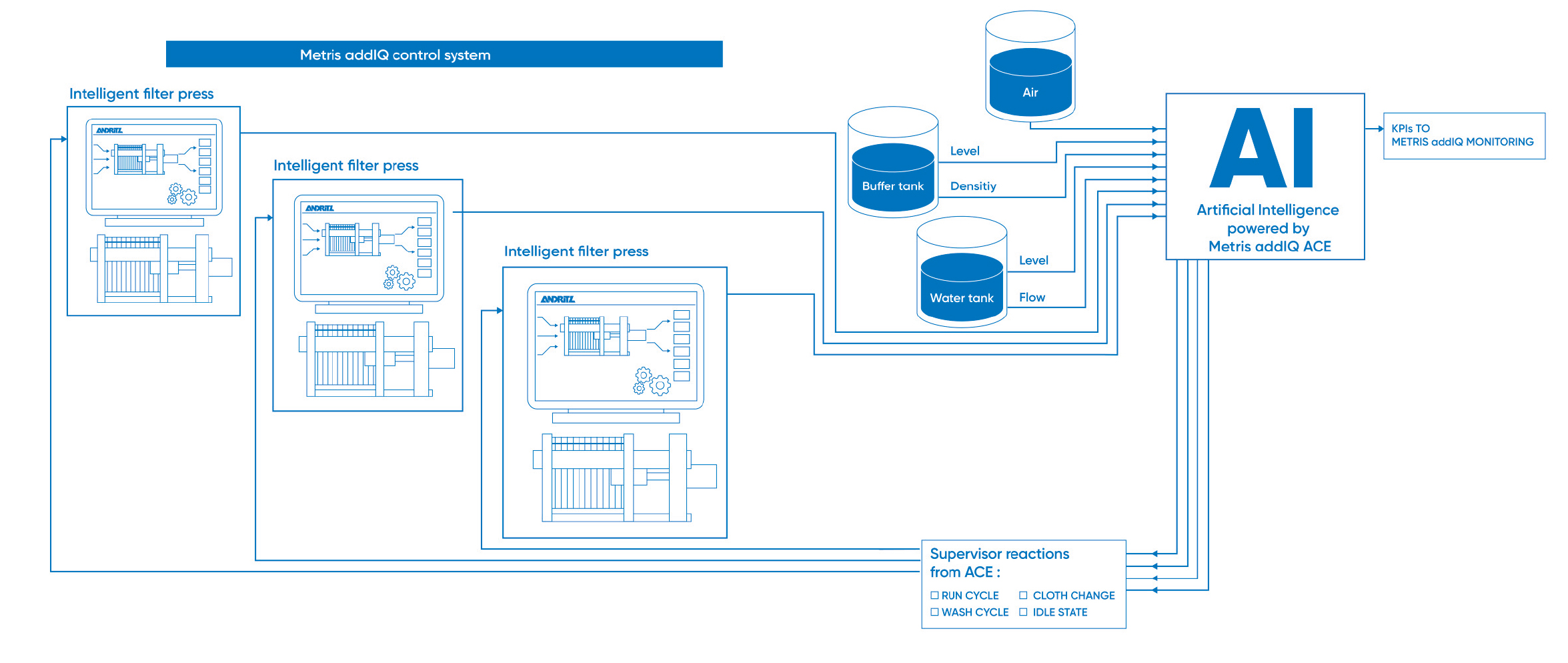

From higher plant efficiency to preventive maintenance and increased profitability, digital innovation is bringing a variety of benefits to industrial operations. ANDRITZ has combined the power of smart sensors, big data analytics, and virtual and augmented reality to create Metris, a portfolio of digital industrial solutions. Within this portfolio, Metris addIQ control systems offer cutting-edge machine and process control for solid/liquid separation equipment and systems.

Metris technologies can be fully tailored to individual requirements and unite the physical and digital worlds, giving plant operators virtual access to ANDRITZ experts whenever they need them. Its automation solutions range from basic automated movement to enabling machines to recognize changes and imbalances within the process, which can help operators to then optimize operations.

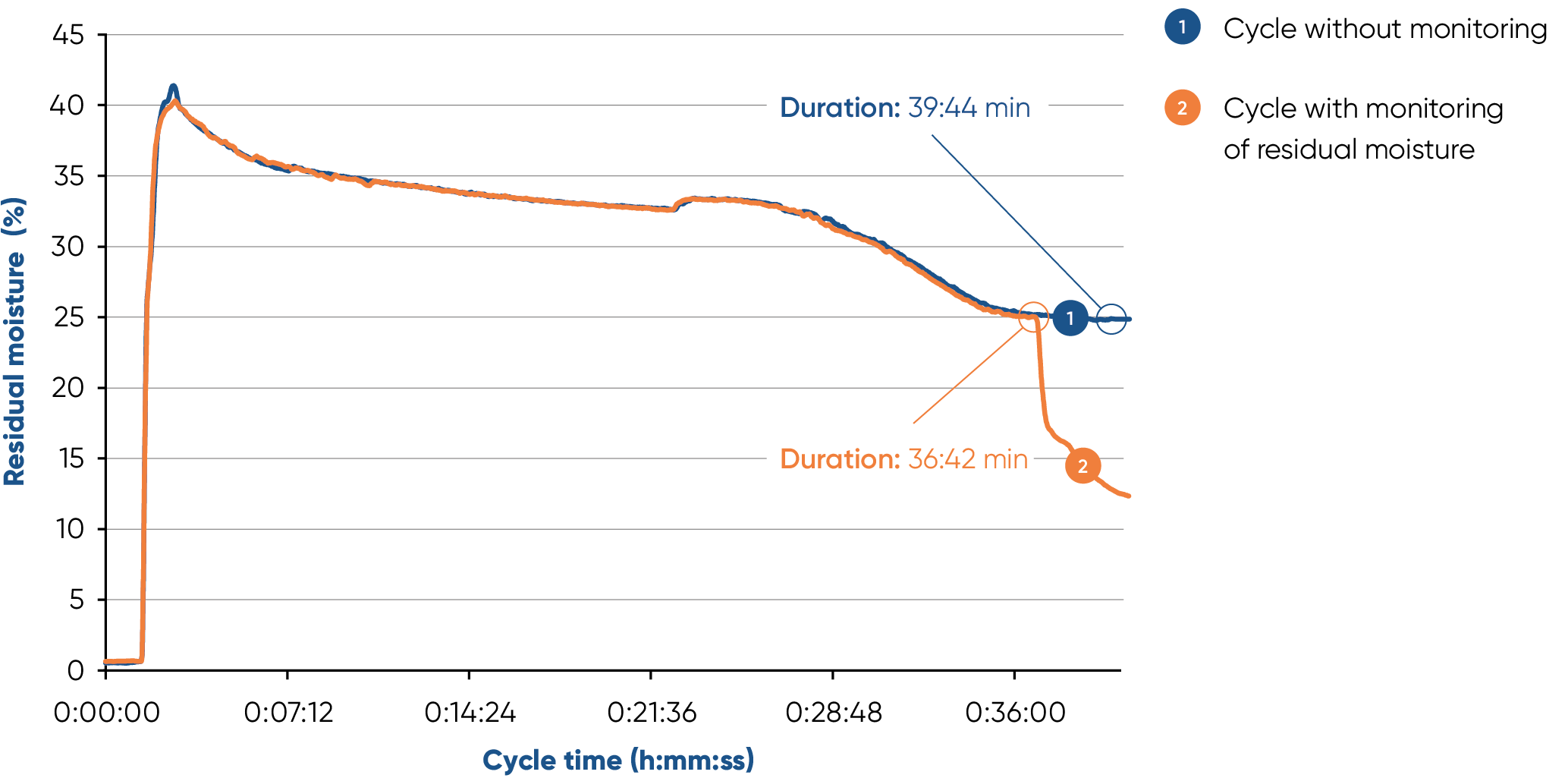

By combining cutting-edge automation solutions with digitalization, Metris addIQ control systems are able to enhance availability, minimize production costs, increase overall equipment efficiency, and reduce the risk of operating errors, resulting in a high level of reliability.