ANDRITZ has experience integrating all of the existing process areas with this new technology specifically for dissolving pulp production. Experienced ANDRITZ project teams give you support during engineering, planning, erection, and start-up of your dissolving pulp production line. Global and local technical and service support is at-the-ready throughout the life of the equipment.

ANDRITZ technologies for dissolving pulp production

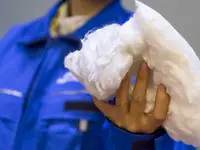

Demands for environmentally friendly fiber sources have dramatically increased the interest in utilizing dissolving pulp, particularly in textile processes. ANDRITZ has a cost-effective approach to dissolving pulp production that includes a new continuous auto-hydrolysis cooking process coupled with efficient washers and other proven downstream pulp processing equipment.

The key challenges are maintaining high yield and productivity while ensuring consistent pulp quality. ANDRITZ technology for the production of dissolving pulp is based on many years of experience with chemical pulp fiberlines and intensive R&D on high alpha-cellulose dissolving pulp grades.

Our experience with biofuels has further led us to design the system with special features considering the optimal methods for by-product recovery and reutilization.

Dissolving pulp production processes and technologies

- A-ConFlex™ flexible continuous kraft & dissolving pulping

- Pulp sheet drying, dissolving pulps

- Evaporation

- Other processes and technologies in common with kraft pulp production