Suzano’s Cerrado pulp project in Mato Grosso do Sul state in mid-western Brazil is progressing well and on schedule to start-up in June 2024. The mill is truly a giant and will be the largest single line eucalyptus mill in the world, producing 2.55 million tons per year of pulp.

Kraft pulp

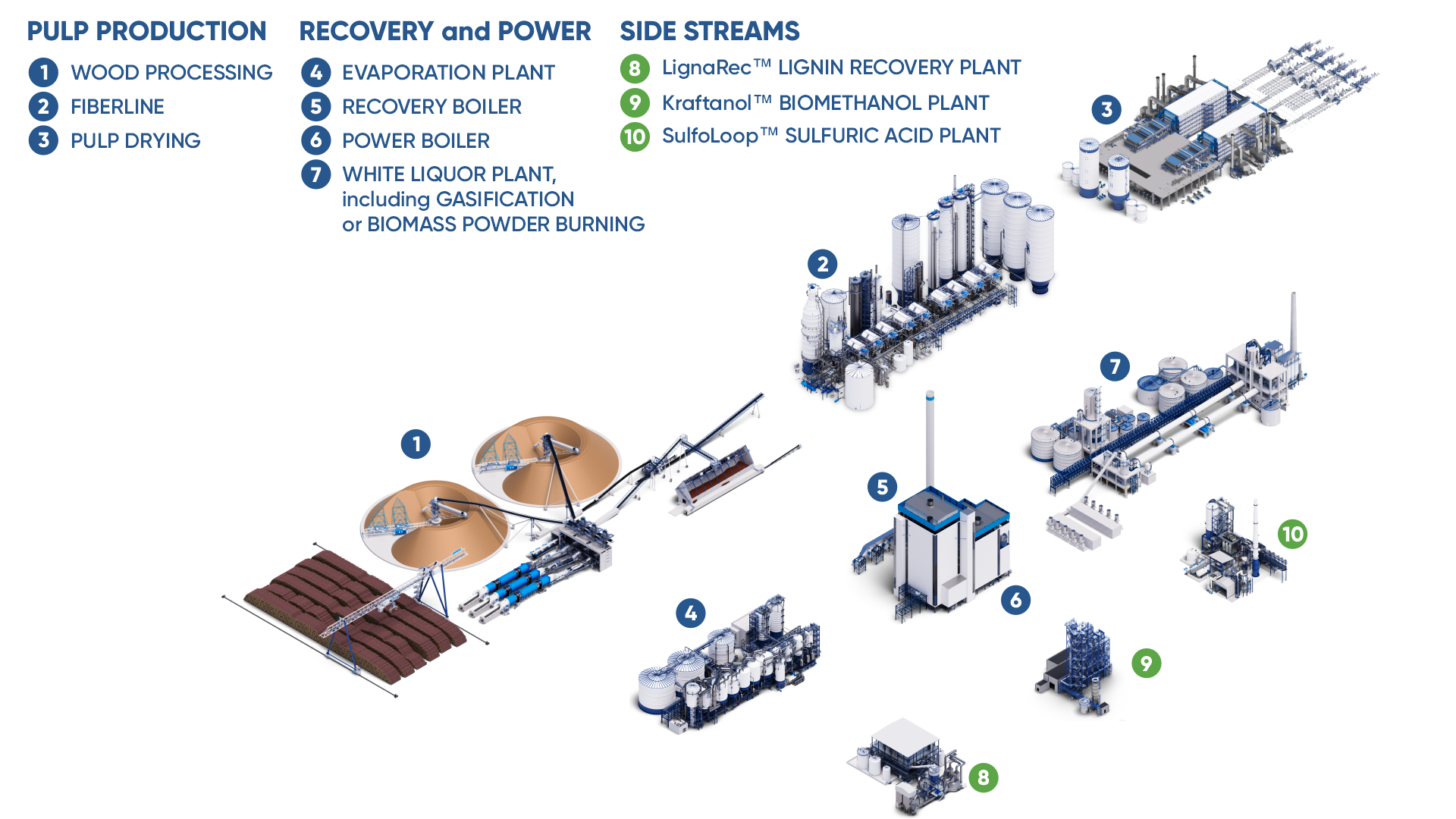

Technologies for every major pulping, recovery, and power process

The major challenges facing pulp producers are to achieve steady-state production of uniform pulp quality with the lowest possible consumption of chemicals and water at the highest efficiency. And to do this within tight environmental regulations.

ANDRITZ is one of the few technology suppliers to deliver a complete kraft pulp mill and to have it performing with world-renowned environmental excellence.