Benefits

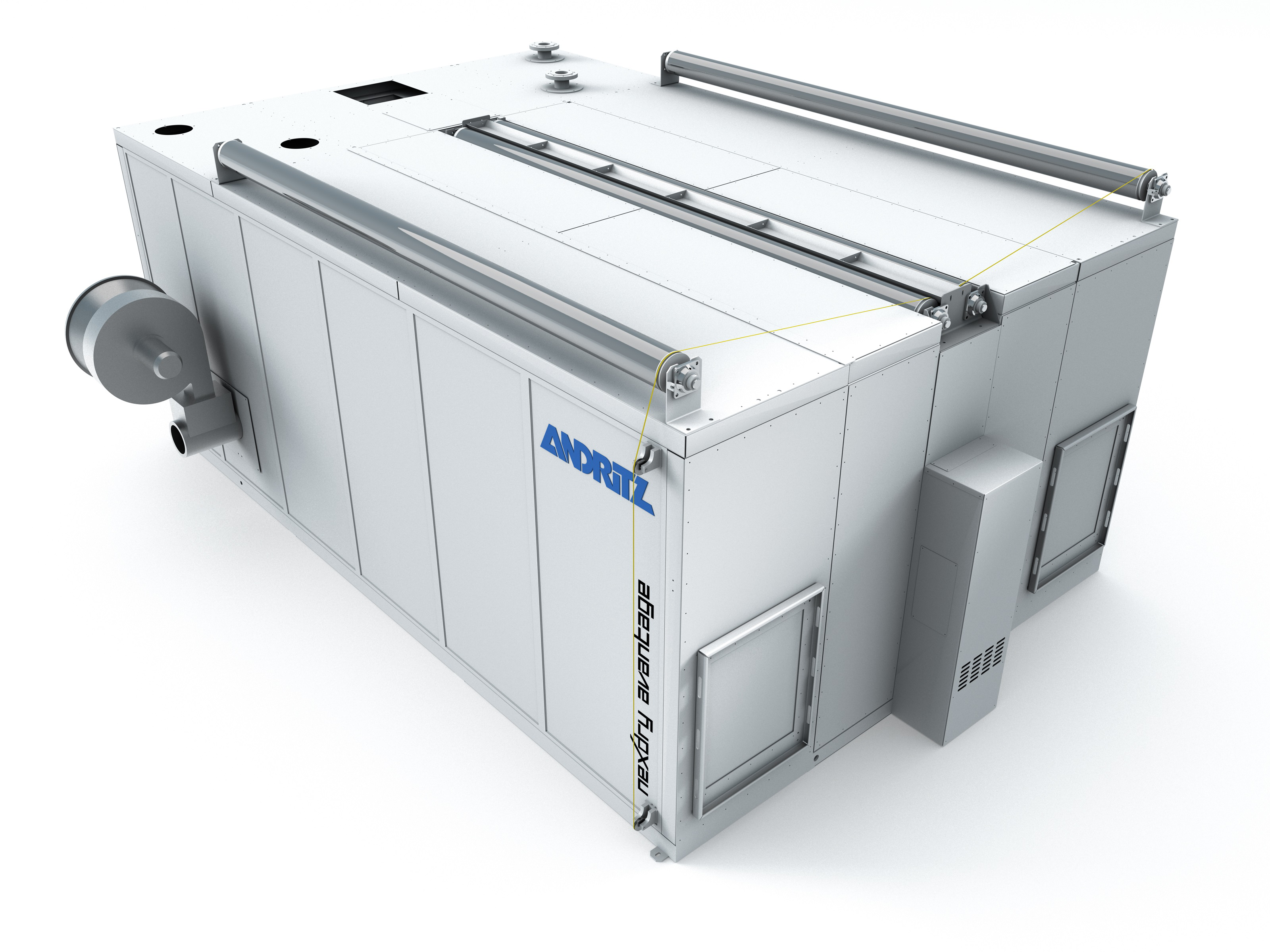

Full access for cleaning and trouble shooting

- Front doors accessing each half hood

- Rear door accessing mixing chamber and fans

- Total access to drum outside and inside

- Exhaust and fresh air dampers on side walls

Easy access for preventive maintenance

- Platforms accessing filters and burners

- Centralized lubrication for drum bearings

- Belt drive for drum = no chain greasing issue

Benefits main fans

- Low pressure drop hood and drum 3000Pa

- Flow 100 000m3/h per fan

- Direct drive

- Integrated fan casing for 78,7% efficiency