Benefits of the ModuScreen F

- Optimized rotor/cylinder combination

- High screening efficiency

- Trouble-free operation

- Modular

- Easy maintenance

- Optimized screening performance with special dilution rotor (patented)

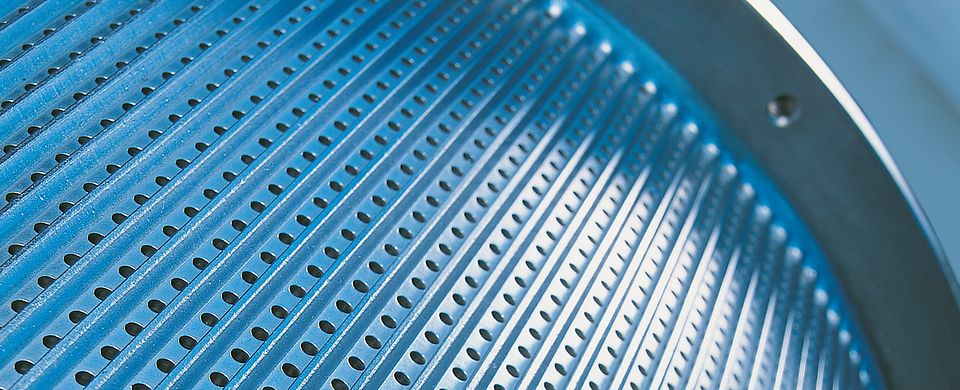

The ModuScreen F is a multi-use screen which can serve as a coarse screen or as a high- and low-consistency fine screen. The ModuScreen F is delivered with a rotor and screen cylinder that is optimized for production requirements, ensuring reliable performance and superior screening efficiency. Screening consistency can range from 1–5% depending on the application.

The ModuScreen D coarse screen can be installed in recycled fiber processing systems where deflaking is required (e.g. (A)OCC, DLK, etc.). The ModuScreen D performs trouble-free even with high levels of contaminants.

Coarse screening ModuScreen F

Coarse screening ModuScreen D

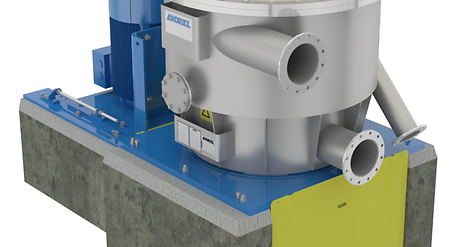

The ANDRITZ ModuScreen CR screen removes heavy particles from recycled fiber furnish. The design combines the benefits of a HD cleaner and conventional coarse screening in one unit. Using this screen allows a mill to install fewer pieces of capital equipment, fewer tanks and pumps, less piping, and fewer valves and instrumentation. Typically, the ModuScreen CR is applied in recycled fiber lines, but it can also be applied in other papermaking applications.

The ModuScreen CR is an inflow type screen and uses stationary foils located inside the cylinder and a rotating screen cylinder. Its unique rotating screen cylinder elevates the ModuScreen CR to be the optimum technical solution for coarse screening today. The foils are only in contact with the accept pulp stream and not with the contaminants. This results in excellent screening performance, low power consumption, and a longer, more reliable life.

Low maintenance costs

Low energy consumption

Coarse screening ModuScreen CR