Effectively handling high-temperature boiler ash

Cost-effective production of energy biomass is very much dependent on efficient handling of available biomass sources, as well as the efficiency of each process. Combusting biomass in a boiler generates ash with high temperatures. This ash (either bottom or fly ash) needs to be cooled and/or processed to a form that can be transported from the power plant.

Complete systems or specific equipment – ANDRITZ has the solution

ANDRITZ offers complete solutions for biomass boiler ash handling. The scope of supply can vary from complete plants to individual equipment delivery. ANDRITZ is very experienced in project management, ensuring deliveries that are on-time and on-budget, and produce excellent economic results for energy producers.

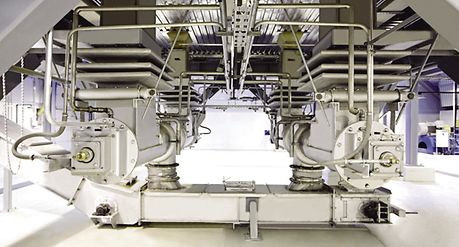

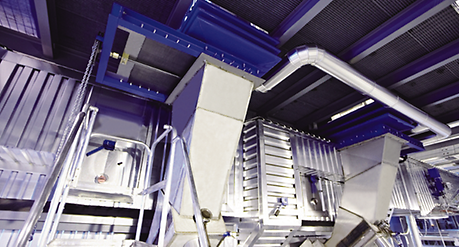

Ash handling systems

ANDRITZ ash handling systems include conveyors and other equipment necessary for removal of bottom ash and fly ash from the power boiler. Water-cooled screws or chain conveyors can be adapted easily for different furnace configurations and for any type of solid fuel being combusted. The system also includes sand handling, including the recycling of sand back to the boiler.