Optimization, data analysis, augmented reality

Vibration analysis

ANDRITZ offers customized solutions for solving vibration issues on your machines, regardless of the OEM or type of machine.

The challenge

The most important topics in every mill are safety and highest energy efficiency, while maintaining the best possible fiber quality. Vibration issues can have an impact on both of these topics and reduce the availability of your machines significantly.

The ANDRITZ solution

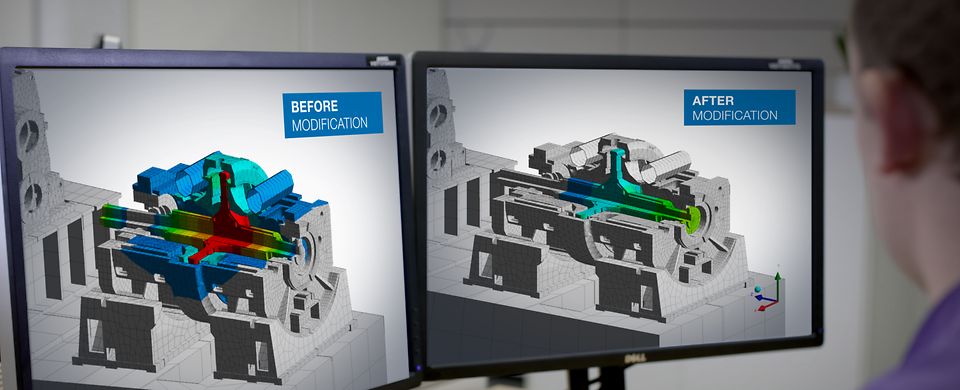

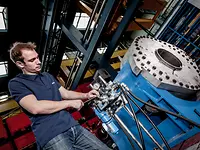

Our latest success story: analysis of a refiner with 23 MW installed power, an operational speed of 2300 rpm, a rotation mass of 29.5 tons, and an overall mass (incl. foundation) of 450 tons. The vibration behavior of the complete system was recorded with multichannel measurements (108 channels). The root cause of the vibration issue was determined by combining the measurement data with simulations. We use finite element methods as well as multibody simulations for modal analysis, critical speed calculations, harmonic response analysis, and transient calculations.

For ANDRITZ, it is crucial to detect and resolve the problem rather than just counteract its impact. Our long-term experience with mechanical equipment enables us to design possible solutions. These solutions will be evaluated in simulations to eliminate any operational risk. Thus, a vibration analysis usually results in a mechanical upgrade of the equipment.

Your benefit is that you have the vibration analysis and the design upgrade from a single source.

Let us be your long-term partner to optimize the performance of your system.