Our papermachine service specialists are skilled and experienced at raising the production efficiency of a machine, sub-process, or production line. Their knowledge helps protect and extend the lifetime of your equipment and lower the overall operating costs.

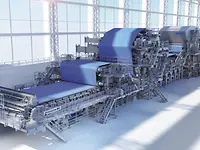

PrimeForm forming sections for paper and board machines

Superior forming solutions setting the standard for quality, capacity, and runnability

The ANDRITZ PrimeForm product family excels in all paper and board applications in the industry, with forming concepts which cover the complete range of Fourdrinier machines, hybrid formers, and gap formers.

Paper properties are strongly influenced by the spatial distribution of the raw materials in the sheet. The optimized design of all PrimeForm forming products, in combination with the PrimeFlow headboxes, delivers excellent paper quality and paper uniformity.

- State-of-the-art sheet forming allows for high production capacity and paper quality

- Compact, efficient design

- Operator requirements for safe handling, cleaning, and maintenance are built in

- Fully cantilevered frame for efficient wire change

PrimeForm TW shoe-blade gap former

Designed as an evolution in traditional gap forming technology, this product has undergone rigorous testing in pilot studies and has been a success in the market for 25 years. The PrimeForm TW shoe-blade gap former is highly versatile, with operating speeds of 1600 m/min and a wide range of grades and furnishes, with single-ply basis weight references from 30 - 250 gsm. The PrimeForm TW shoe-blade is the preferred choice when excellent paper formation, high dewatering capacity, and flexible operation are essential. Solutions are available for both rebuilds and new machines, offering outstanding production output with minimal specific energy consumption.

- Reliable, record setting performance

- Flexible on-the-run adjustment for optimal formation, strength, and CD uniformity

- Global expertise, local support

- Exceptional cleanliness and runnability with high sheet solids.

HEINZEL Steyrermuehl PM6

PrimeForm HB

A Fourdrinier section with a hybrid former has a much higher drainage capacity and significantly improves sheet quality, including better formation and z-direction distribution of fines and filler. The PrimeForm HB is a state-of-the-art hybrid former designed for operating speeds of up to 1,200 m/min. It provides exceptional operational flexibility and optimized sheet handling. Its curved blade path enables the PrimeForm HB to support applications ranging from 18 - 700 gsm. Its low-intensity dewatering strategy enables inlet consistencies as low as 1.2% without crushing the sheet, making the PrimeForm HB the market leader in overall dewatering capacity. This former is the perfect choice when the objectives are formation and formation-driven property enhancement, such as strength and smoothness. Furthermore, many of the PrimeForm HB benefits can be achieved with minor cover rebuilds, making the change an easy, low-cost option.

- Highest dewatering capacity on the market (2-3 times greater than other designs).

- Market leader in minimally invasive rebuilds.

- Low inlet consistencies promote formation and related property improvement.

- Flexible roll configuration is available for low-space applications.

Gascogne Papier PM7

PrimeForm SW

The PrimeForm SW product range offers various solutions for conventional Fourdrinier sections, tailored to the requirements of any paper or board grade and basis weight. With a broad range of working widths and machine speeds of up to 1,300 m/min, there are designs available with single and multiple Fourdrinier sections. The compact design of the PrimeForm SW simplifies installation in new machines or rebuild situations. The result is the production of high-quality paper with a rapid startup curve, backed by fabrics & rolls and service support from ANDRITZ.

- Highly flexible solutions for traditional paper machines.

- Dewatering capacity coupled with table harmonics improves sheet strength.

- Adjustable foils and agitators optimize table activity.

- Ergonomic and clean design focus.

HEINZEL Poels PM3

PrimeForm TW roll-blade gap former

The PrimeForm TW roll-blade gap former delivers excellent performance at high speeds, with minimal two-sidedness and solid dewatering. Grammages from 90 - 160 gsm are accommodated. Gentle dewatering in the forming roll area ensures high retention. The increased fines content benefits strength development in the final sheet. Forming shoes on both the top and bottom generate optimized dewatering within a wide operating window.

- High dewatering capacity

- Elimination of two-sidedness

- Well-proven gap forming concept

- Excellent formation and strength properties

HEINZEL Laakirchen PM10