Older methods — less than ideal

There are significant challenges in the removal of hemicelluloses when producing dissolving pulp with a continuous cooking system. Achieving stable production and avoiding the precipitation of by-products from the cooking reaction were common difficulties in older systems that led to operational and quality issues.

Advanced and effective cooking for dissolving pulps

ANDRITZ took a fresh look at the process and re-designed its cooking system to make the removal of hemicellulose much more effective. The foundation for modifying the process and producing new equipment components is based on years of experience in producing pulps for paper grades. The ANDRITZ technology has gained rapid acceptance and has been delivered to several mills in Asia where viscose fiber growth is the highest.

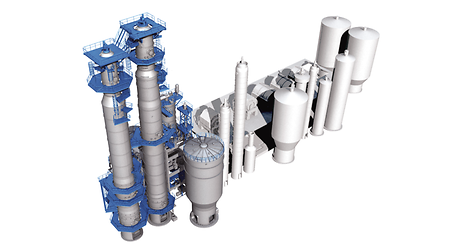

The A-ConFlex™ technology utilizes autohydrolysis for efficient hemicellulose removal. This allows the recovery of the hydrolysate, which contains dissolved hemicellulose, in a water solution. The process is simplified and costs are reduced since autohydrolysis does not require additional chemicals in order to start the hydrolysis reaction. This process is carried out in a separate vessel installed in front of the continuous digester.

A-ConFlex™ — Flexibility in continuous kraft & dissolving pulping

The A-ConFlex™ technology can be retrofitted to existing continuous cooking installations. Installation and operational costs are likely to be much lower than traditional cooking systems for dissolving pulps. Fiber yields are expected to be several percentage points higher than batch technologies due to excellent selectivity of the principle reactions and controlled, sustainable recovery of by-products.

Current practice for handling the hydrolysate is to neutralize it and combust it with the bulk black liquor. But this valuable stream can also be used—and is already being used by some of our customers—as a building block in the production of other added-value bio-products, such as xylose and furfural, further improving the economics of the overall pulping process.