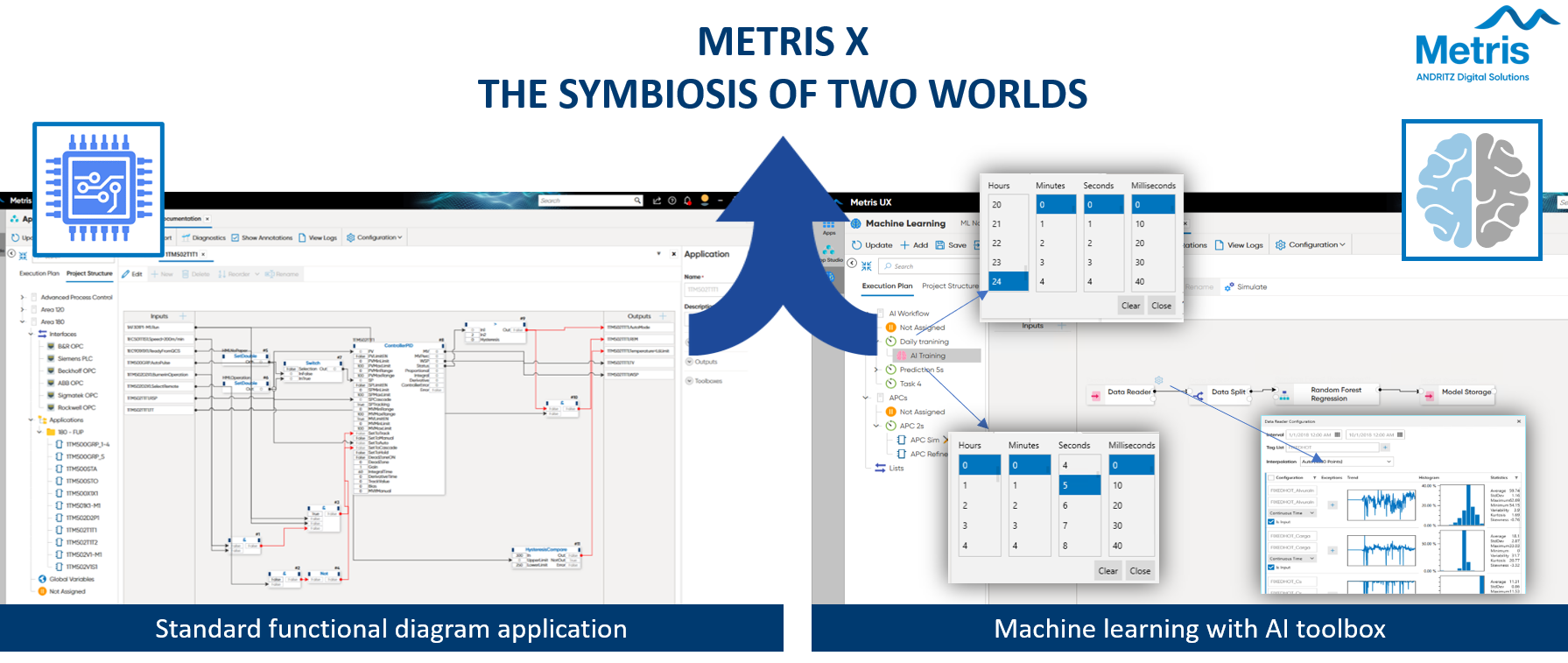

Metris X – the Symbiosis of two worlds – Automation and Machine Learning

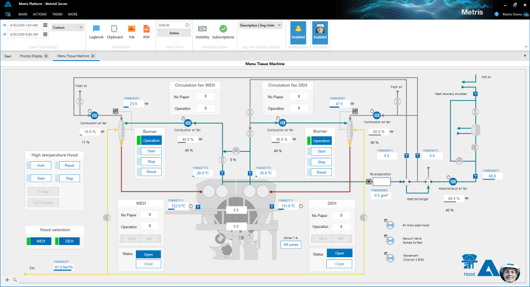

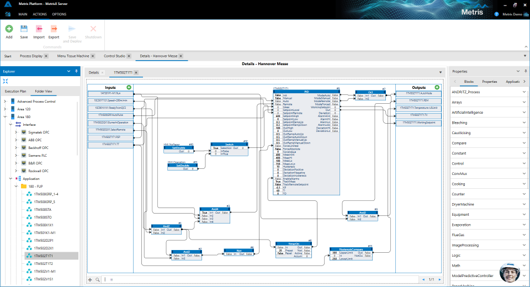

With Metris X, ANDRITZ combines the worlds of Automation and Machine learning in one solution. On the one hand, the world of data scientists and, on the other hand, the world of process plant automation engineers, which are now merged together into one environment.

With the open integration of different Data Scientist tools (Machine Learning Notebooks), ANDRITZ Automation offers a seamless integrated working environment for Data Scientists coming straight from university and enabling AI applications without plant engineering knowledge. Universally known AI development environments, such as Google Tensor Flow, Python, etc., provide the integrated foundation for building AI-based methods and models.

Automation engineers have now in addition the ability to create and train these AI models directly using the same automation engineering environment. The AI-based models appear like standard function blocks in the controller and thus can be used directly by automation engineers for open- and closed-loop control tasks.