Meet ANDRITZ Nonwoven & Textile all over the world

High-efficiency dewatering

Given rising energy costs, a potential area of savings is the dewatering/drying process after hydroentanglement.

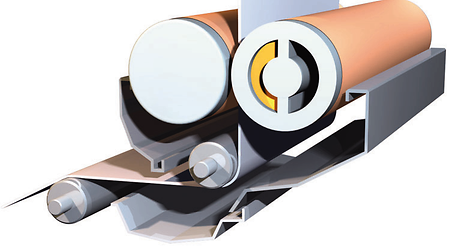

The improved dewatering efficiency at reduced power consumption with neXaqua significantly reduces energy costs. neXaqua is a high-efficiency squeezing device using S-Roll technology. State-of-the-art spunlace production, which includes suction slots and through-air drying, is now enhanced with the neXaqua dewatering step. The technology combines vacuum, mechanical, and thermal dewatering for the highest dewatering efficiency. It can be retrofitted to existing lines as well.

ANDRITZ Nonwoven follows a systematic approach to optimize the dewatering process in each plant: analysis of base materials, production speeds, squeezer set-up, and so on. Tailor-made solutions are obtained based on extensive experience. The recommendations can be backed by trials conducted at our pilot facility.

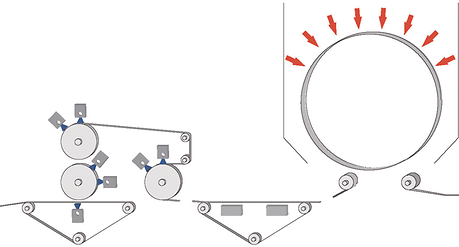

Conventional dewatering process in spunlace production

neXaqua - high-efficiency dewatering with S-Roll technology