up to 5%-units

higher dry solids content

How to remove moisture from bark in an economical and reliable way?

The ANDRITZ HQ-Press delivers bark with approximately 5%-units higher dry solids content than any competitive unit. This can increase the net green energy value of the bark up to 15%.

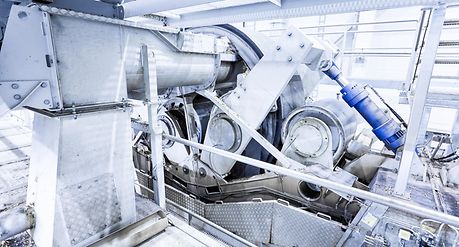

Unlike competitive units which have enclosed structures, the HQ-Press has an open, simple design. The components are easily accessible for maintenance. As a side benefit, the open design helps with housekeeping activities.

HQ-Press is a robust, reliable solution for bark handling in any woodyard or biomass handling operation.

higher dry solids content

higher green energy value

loose capacity

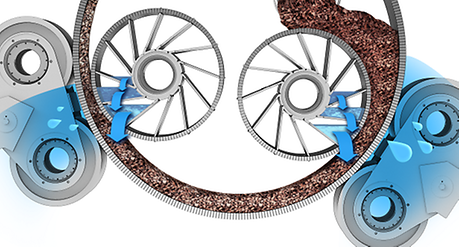

The design of the HQ-Press features a self-orienting drum with two-phase pressing to achieve the higher dryness. While conventional presses typically achieve an annual average of 40% dry solids, the HQ-Press is able to deliver an annual average of 45% dry solids in normal operation. Advanced controls on the unit maximize the output under a variety of operating conditions.

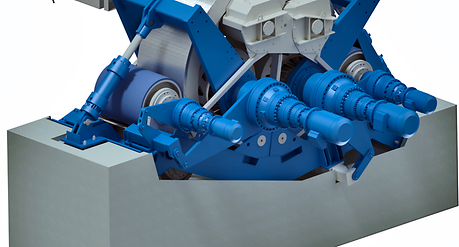

3d rendering of the HQ-Press

HQ-Press operation principle