Cleaning recovery boilers to maintain efficient operation presents challenges and potential hazards to personnel. Diamond Power recovery boiler cleaning components provide hands-free, automatic cleaning operations which are proven to optimize boiler performance – all while improving worker safety.

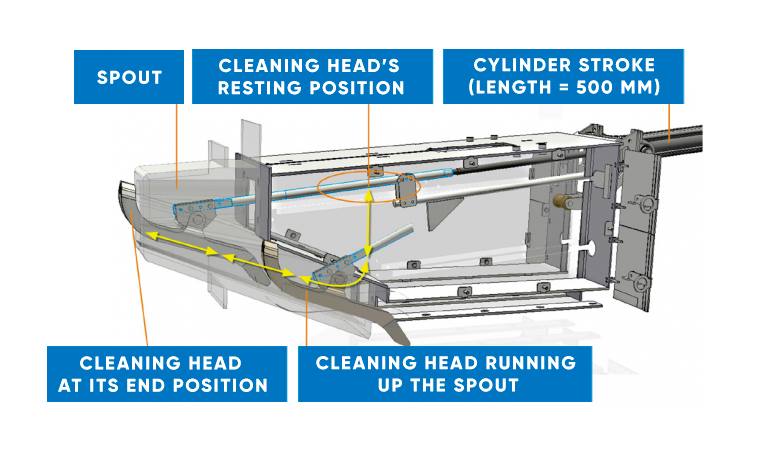

Diamond Power recovery boiler cleaning solutions and specialized equipment include a range of dependable port rodders (air port cleaners), dampers and cleaning components including the SprayRod liquor gun cleaner, dual rail liquor gun station, FlexRod port rodder, SpoutRunner Smelt spout cleaners and Velocity Wing air flow damper. These components are available for all manufacturers’ recovery boilers.

Quality components for cleaning recovery boilers