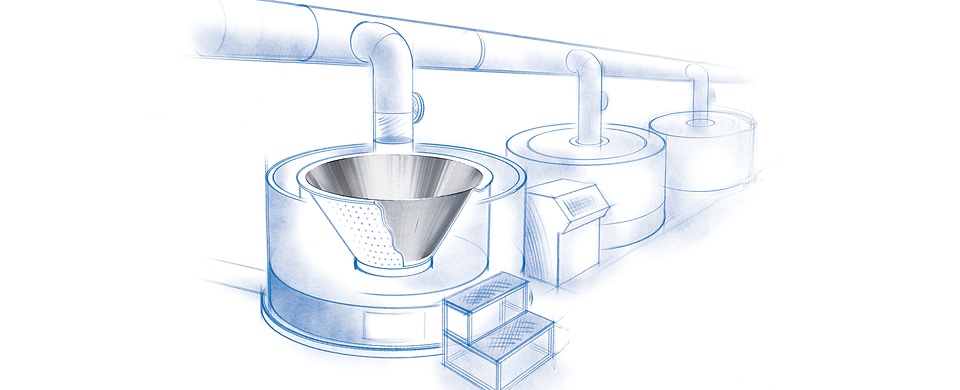

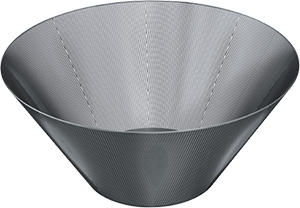

Monocone separation screen

Unlike screens with short vertical slots, polished wedge wire screens with continuous horizontal slots enable the rapid separation of sugar crystals and molasses, as well as friction-optimised conveyance of the sugar crystals across the screen surface. When using polished wedge wire screens for continuous centrifuges, the horizontal slots ensure that the crystals do not break. The stroboscopic test shows that the crystals take a much gentler path across the surface of the wedge wire screen than with screens with vertical slots. Wedge wire screens are significantly more robust than common screens and therefore more resistant to damage caused by foreign bodies or encrustation. All of our baskets for continuous centrifuges are manufactured from 1.4401/1.4404 (316/316L stainless steel), internationally recognised alloys for the food industry. In contrast to the standard CrNi foils, the materials used by ANDRITZ do not cause any chrome or nickel contamination.

Benefits Process:

- Higher sugar retention (up to 2% more)

- Fast separation of sugar crystals from the molasses

- High wear resistance: Low risk of sugar encrustation and damage by foreign substances

- Larger sugar crystals, less breakage

- No nickel or chrome contamination of the final product

- Increased production capacity due to higher open area and optimised profile wire geometry

Benefits Maintenance:

- No losses due to business interruption with frequent, unplanned screen changes

- Reduced maintenance effort

- No design changes to your machinery necessary

- No balancing required

- No downtime during the project

- Low maintenance costs