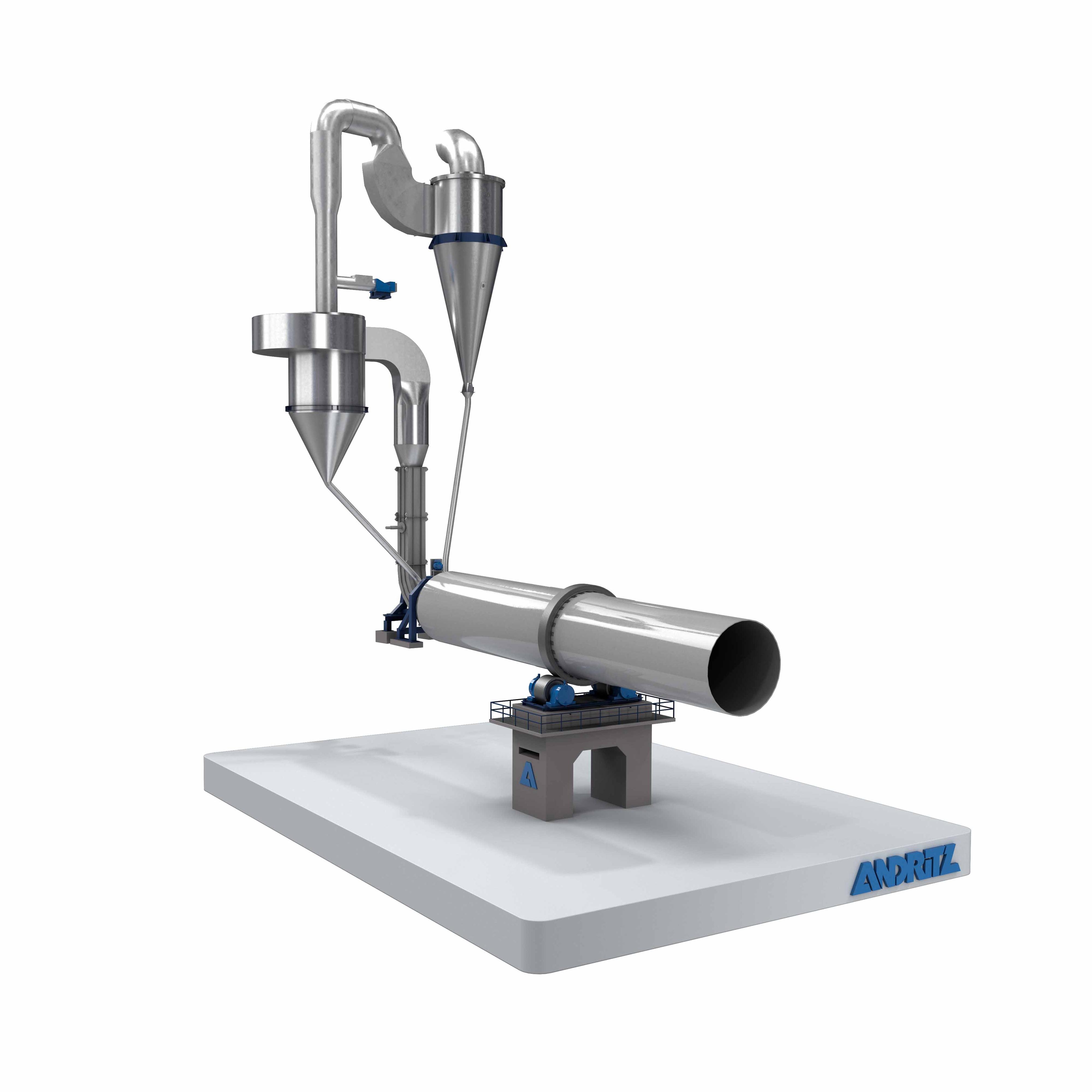

LimeDry-H

LIME MUD DRYING SYSTEM

ANDRITZ has made significant improvements to its LimeDry mud drying system. Utilizing some of the proven concepts featured on the latest LimeWhite-H white liquor disc filter, for example, the implementation of center shaft axial movement, a hollow shaft, and fixed scraper – similar, tailored principles have been applied to the LimeDry-H lime mud drying system.

The end result is a more simplified vat construction and stable feeding system, providing increased homogenous lime mud that enables less swinging of temperatures in the flue gases of the lime kiln and, ultimately, savings in energy.

The new system comes with a smaller footprint, which saves space and investment costs, as well as an updated design, which improves maintenance access and provides a safer working environment.