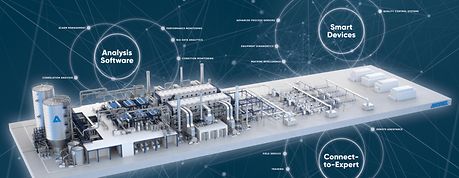

The innovative Metris DryQ™ pulp drying solution designed by ANDRITZ is an intelligent solution for the pulp drying system. The introduction of our DryQ pulp drying solution allows you to measure, and therefore manage, your whole production process through innovative digital solutions.

What are the latest developments for achieving maximum availability in the drying line?

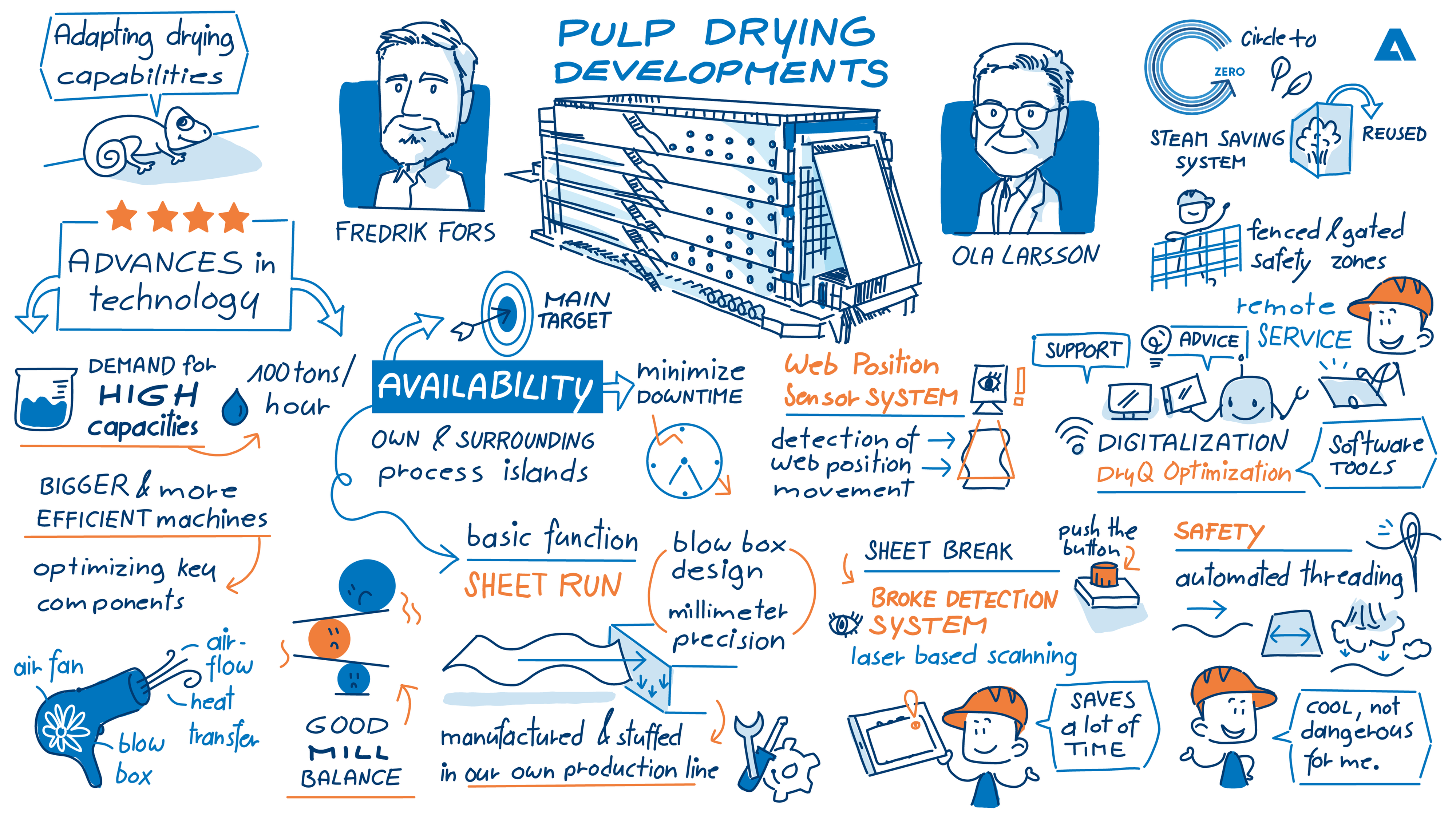

Pulp mills are getting bigger, faster and more efficient. Today a full-size drying line can handle a web width of over 10 meters. ANDRITZ drying lines have come a long way in a short space of time to keep up with the fast evolution taking place in pulp mills.

Fredrik Fors, Product Manager, Pulp Drying at ANDRITZ says, “In our development work we thought we were aiming at the sky targeting a capacity of at least 5,000 tons per day, that´s almost 50% more than we had ever built before. Today, we see that customers are already challenging us with this figure and even more.”

Listen to this deep-dive episode to learn more about significant developments in the pulp drying line over recent years and, how ANDRITZ has dealt with this rapid ramp up of capacity!

Season 1 / Episode #07

GUESTS IN THIS EPISODE:

Ola Larsson,

Director of Technology and R&D,

Pulp Drying, ANDRITZ

Fredrik Fors,

Product Manager,

Pulp Drying, ANDRITZ