THE ZMS SCHWANDORF PLANT IN NUMBERS

The Schwandorf waste-to-energy plant supplies the neighboring company Nabaltec with low-cost energy. The waste-to-energy plant also feeds heat into the Schwandorf district heating network and electricity into the public grid.

ENERGY GENERATION IN FIGURES:

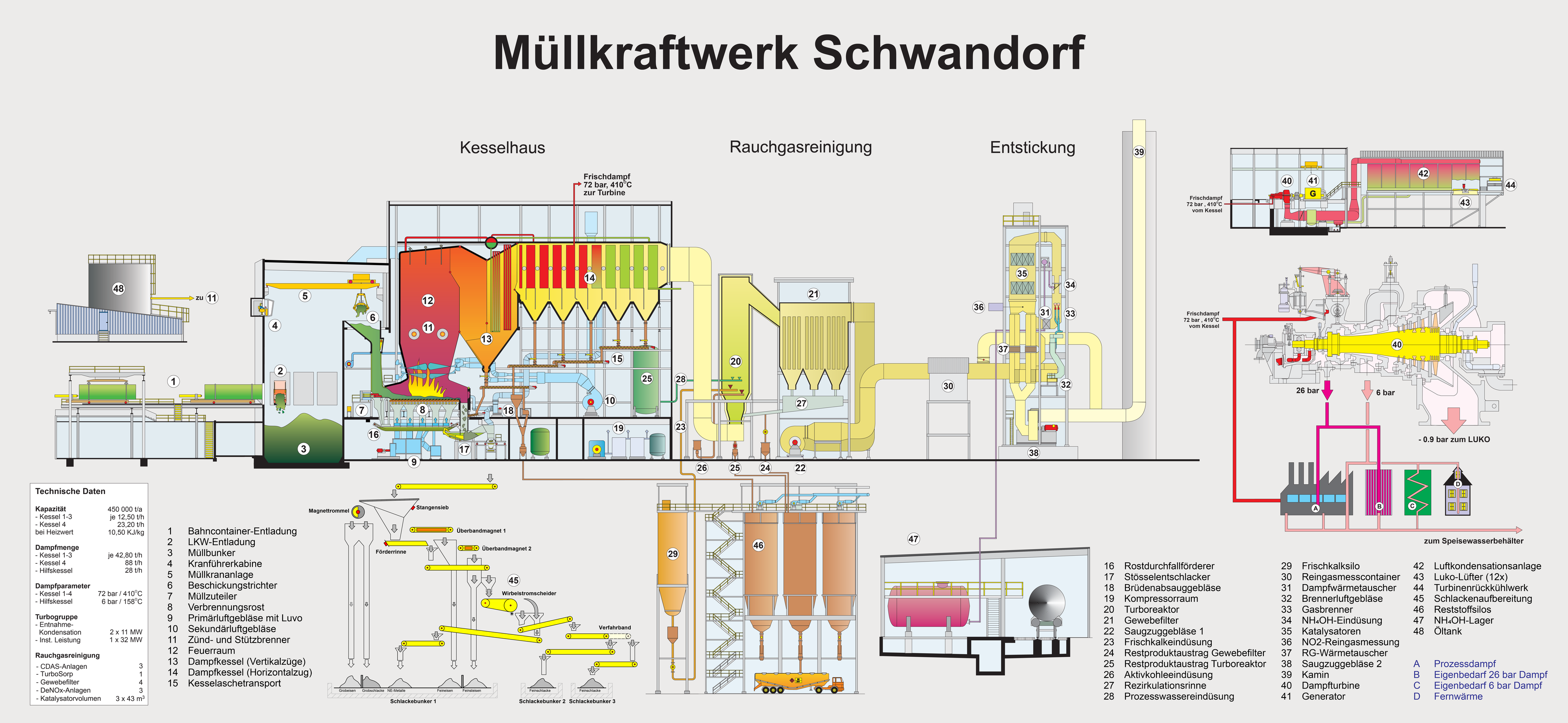

- The hot flue gases from waste incineration are used to generate high-pressure steam at a pressure of 72 bar and a temperature of 410°C in the steam boilers. Of this, about 7% percent is used for the company's own needs and approximately 2% for the neighboring industrial plant

- The largest portion (about 91%) drives three turbines with generators (2 x 12 MW, 1 x 32 MW) installed in the Schwandorf waste-to-energy plant and generates electricity.

- As the steam passes through the turbines, it expands and can be extracted as medium-pressure steam (26 bar, 350 °C) or low-pressure steam (6 bar, 160 °C).

- The amount of extracted steam corresponds to about 55% of the originally generated high-pressure steam in the plant and is used for the internal requirements of the waste-to-energy plant (about 29%), as process steam for production purposes in the neighboring industrial plant and in the sewage sludge drying plant (about 54%), as well as for generating 90,000 MWh of district heating for the city of Schwandorf (about 17%).

- Of the electricity generated by the generators, about 20% is used for the company's own needs, while the remaining 80% is supplied externally.

- The energy content of the waste processed in the waste-to-energy plant in 2024 would substitute approximately 115 million liters of heating oil.