The global economy is in constant need of power, which is still mainly provided by coal, oil and gas – fossil fuels that are finite and harmful to the environment over their whole value chain. Other more sustainable resources such as municipal waste or sludge have started to establish their position in the industry and are gaining more attention now due to the global effort to develop and install solutions that will minimize CO2 emissions.

Waste – Sludge – Refuse Derived Fuels – Industries

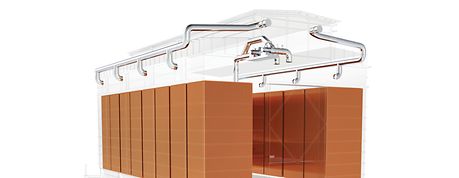

Waste incineration, sewage sludge treatment and/or refuse derived fuels combustion require multiple and very performant emissions reduction and energy recovery technologies.

For ANDRITZ’s customers, Waste-, Sludge-to-Energy, Refuse Derived Fuels and/or Hazardous Waste plants must fully integrate their various streams into today’s sustainability and circularity principles.

Depending on the fuels and local requirements, ANDRITZ’s offers a wide range of multistage solutions which reduce the emissions to the air while minimizing and/or eliminating the liquid effluents and the solids by-products. Also, the latent heat in the flue gases is recovered and further processed into practical forms of energy like heat for district heating or process steam. In addition of being a source of reliable and affordable energy, ANDRITZ can also offer its customer to have their plants acting as carbon sink when installing a CO2 capture unit.

By combing the offering of ANDRITZ Boiler (grate, CFB, …), Green Hydrogen and e-fuels divisions, customers have with ANDRITZ a one-stop shop for all sustainable energy solutions and services.