The ESP uses electrical forces to remove Particulate Matter (PM) from the flue gases. A high voltage source, generating a corona current, charges the PM which migrate to the collecting plate. PM are removed from the plate by a knocking action.

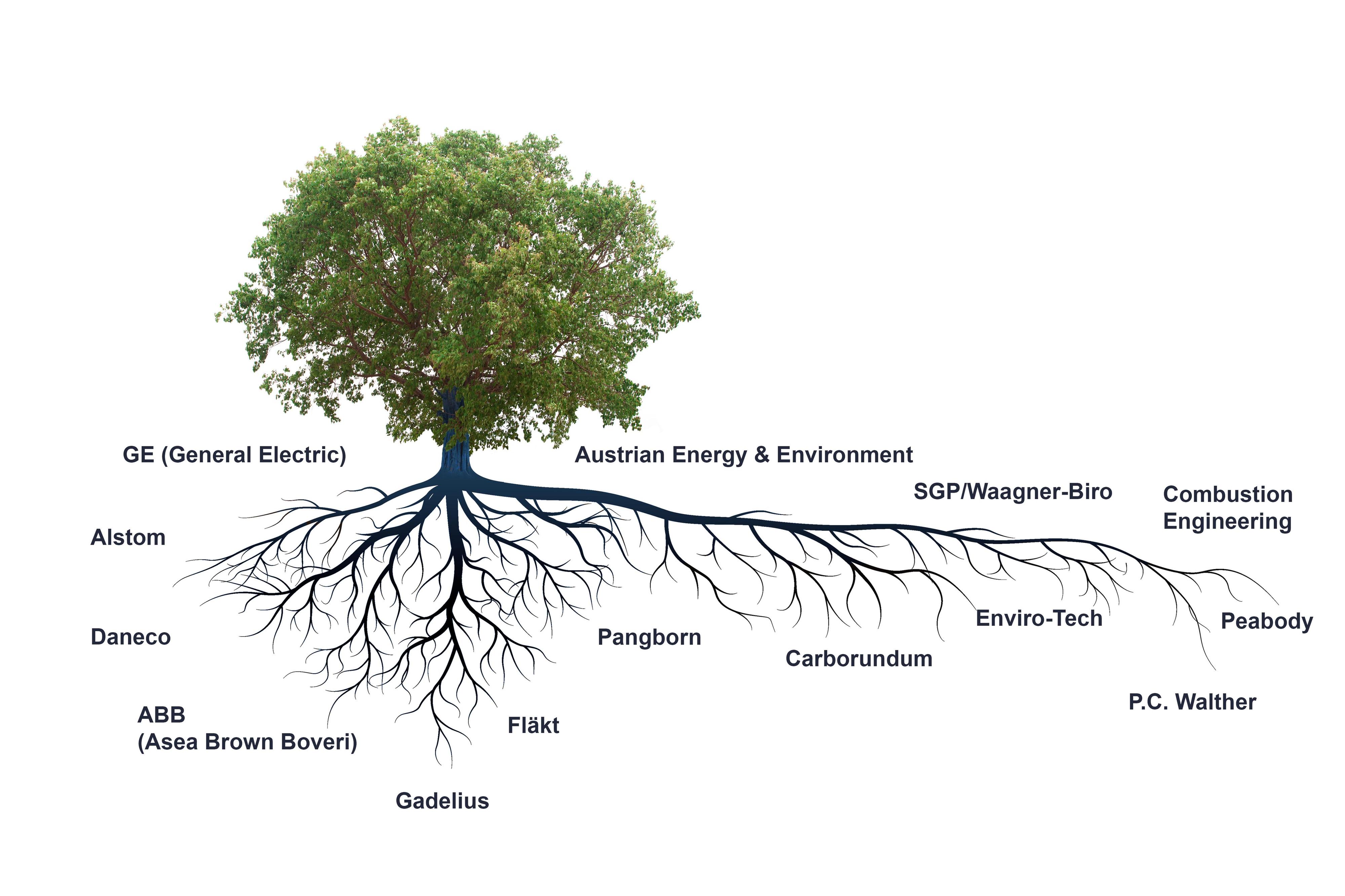

ANDRITZ has acquired parts of GE Steam Power’s AQCS business

International technology group ANDRITZ (headquartered in Graz, Austria) and GE Steam Power (located in Baden, Switzerland) signed a contract in 2021 to acquire GE’s portfolio.

- industrial dedusting (dry and wet electrostatic precipitators – ESP), including the Switched Integrated Rectifier (SIR) and other control systems (EPIC, ERIC, …),

- fabric filters, including EFFIC controller and OPTIPOW pulse valves,

- multi-pollutants treatment (Novel Integrated Desulphurization (NID) and Spray Dryer Absorber (SDA) with atomizer),

- and industrial scrubbing, including condensation scrubbers and low-temperature heat recovery solutions.

The acquisition also includes the main technology center in Växjö, Sweden, as well as employees involved in this business in Europe, South America and Asia.

ANDRITZ has many years of experience in designing and building air pollution control (APC) equipment based on its own technologies and expertise.

With this acquisition, ANDRITZ is expanding its portfolio of products and technologies as well as its capabilities to continue offering you the most innovative, optimized solutions for new-build projects. In addition, ANDRITZ will remain your preferred service provider for inspections, assessments, spare parts, repairs, upgrades and retrofits to the following legacy original equipment manufacturers: