ANDRITZ' footprint

High Head Turbines

Meeting new performance needs

Within the European hydropower sector, much of the current market focus concerns the rehabilitation and upgrade of Pelton turbines. Due to their cyclic loading, Pelton runners have a limited lifespan and there is consequently no alternative but to replace runners when these machines reach the end of their operational life. Given the aging European fleet, this is an important driver for this regional focus on refurbishment. Moreover, refurbishing existing units presents an opportunity to upgrade these machines by adapting or even replacing components to achieve higher performance and improve their suitability to new operating conditions.

The difference between planned and effective operating range can be significant for some plants. Operating conditions can change very quickly depending on the particular services required from a plant. Adapted designs can thus generate a much higher return on investment. Peak output is no longer the sole driver for hydropower performance and today flexibility and good operating conditions over the entire operating range has significant market value.

A new generation of hydraulic runner profiles, the so-called Alpha generation, delivers high performance while being specifically adapted to the operational environment as required. Among other design parameters is the need to integrate the given operating head, with special care required to avoid cavitation in case of very high heads. In addition, in the Alpine region more and more consideration is being given to hydro-abrasive erosion resistance.

Recent projects in Europe and elsewhere with heads above 900 meters are representative of this new generation of designs. With high efficiencies over the entire operational range, wet parts are protected with erosion-resistant coatings that extend life cycles significantly. The La Coche hydropower project in France is an excellent example of this cutting edge approach to Pelton turbine hydropower design. (see article "France")

A number of rehabilitation projects, such as Villarodin and La Bathie in France and Sy-Sima in Norway, are other examples of Pelton units that required new runners and which presented the opportunity to significantly improve overall plant performance.

Technology developments support these evolving market needs, backed with significant investment from ANDRITZ Hydro. Examples include experimental facilities for testing high-performance scale-model Pelton machines or the development of new hydro-abrasion resistant coatings in the ANDRITZ Hydro hydraulic laboratory at Vevey, Switzerland.

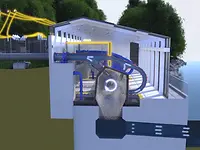

This philosophy is very much in line with continuous development in mechanical engineering to improve the maintenance “friendliness” of Pelton components. It also goes together with novel concepts, such as the patented bolted runner technology, that again aim to simplify maintenance and optimize maintenance costs, especially in hydro-abrasive environments.

Managing, assessing and ultimately determining the operational life of aging components is also an important driver for further technology development. Managing the end of the operational life of Pelton runners is a major concern for numerous Pelton unit operators in Europe and elsewhere. Monitoring, assessing the aging of runners, and establishing adequate maintenance and inspection procedures to provide a continuous assessment of the operational life of aged runners is therefore of strategic importance to many owners and operators.

It calls for the development of new services in the residual life analysis of Pelton runners and, when relevant, specific monitoring and predictive measures. For instance, the Metris DiOMera platform includes features dedicated to the optimization of operations and maintenance regimes of hydro units. (See also article "For a better performance")

The spectrum of Pelton projects within Europe ad-dresses the entire operational life of Pelton units, calling for excellence in services, technology expertise, and continuous development. ANDRITZ Hydro delivers this excellence on a daily basis and continues to lead the technology advances that meet constantly evolving customer needs.