Double production capacity

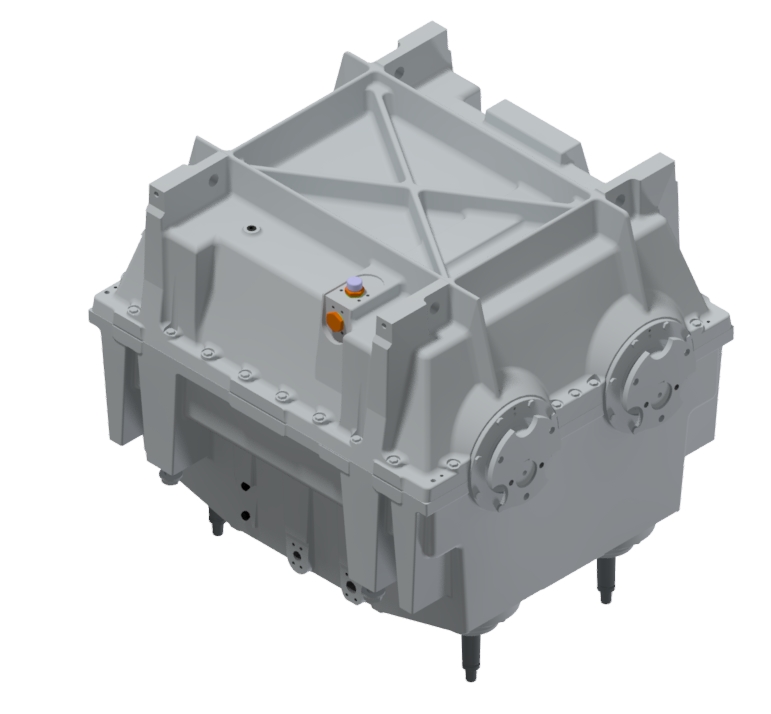

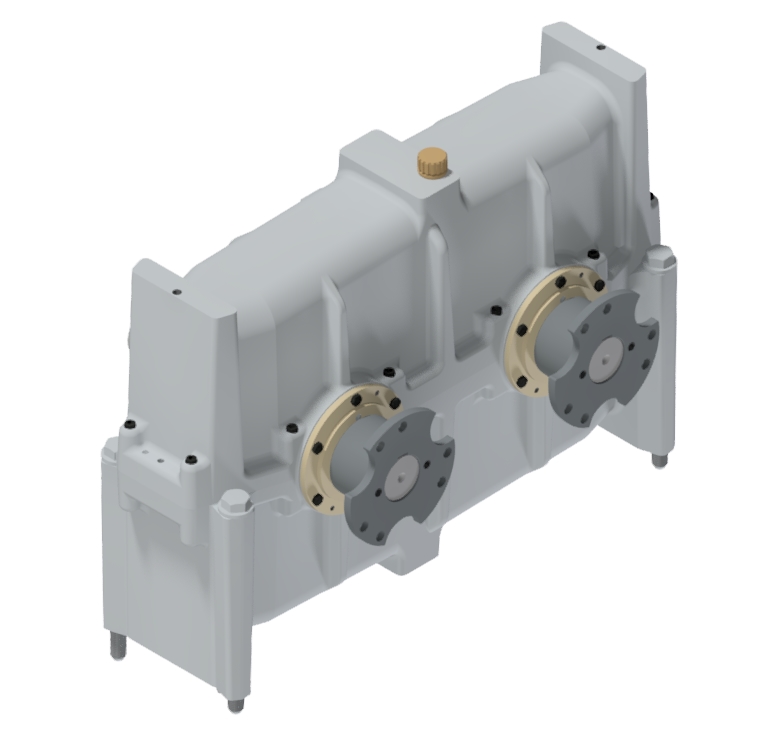

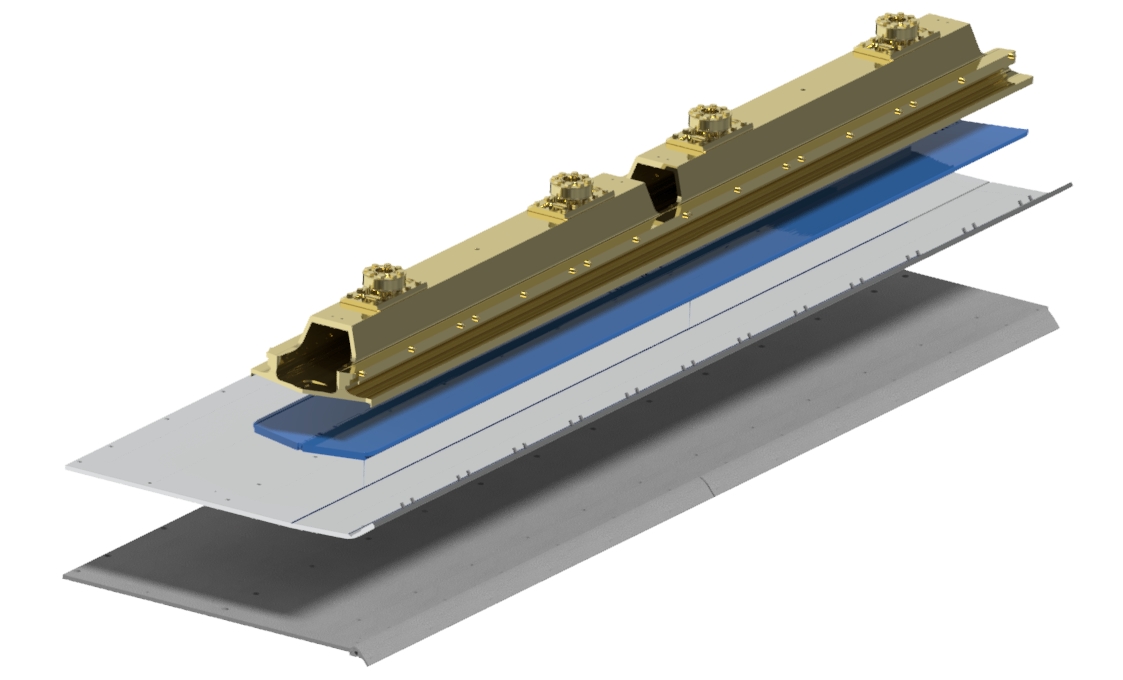

The capacities at ANDRITZ Asselin-Thibeau have been significantly increased and the additional space creates room for more capacities, also in the service area. Among other things, for new and renewed modules as well as reversing boxes and, above all, for material storage and the resulting increase in the number of spare parts in stock as well as a restructuring of material management. Special tools for handling the modules to optimize productivity and safety ensure smooth processing. Quality control and traceability have also been optimized and are state of the art.