Get in contact and unlock the full potential of needlepunch technology with our Technical Center experts!

Whether you’re looking for innovative solutions, technical advice, or support for your next project, our specialists are here to help. With deep expertise and hands-on experience, we provide guidance tailored to your specific needs—ensuring efficiency, quality, and performance at every step.

Fully equipped technical center for needlepunch technology

Located in Elbeuf, France, the ANDRITZ Nonwoven needlepunch technical center is equipped with a pilot line, designed on industrial scale. The installation combines all the latest technology developments by ANDRITZ for the needlepunch market.

The neXline needlepunch pilot line includes a high-performance eXcelle double card designed to run short and long staple fibers with a very uniform web aspect despite throughput capabilities in excess of 500 kg/h/m. It can be set to provide highly uniform webs with MD/CD ratios of less than 3:1. The line is capable of producing needled felts with low to high elongation percentages, with high tensile strength values. Final MD/CD tensile strength ratios of 1:1 will be possible once the felt reaches the winder.

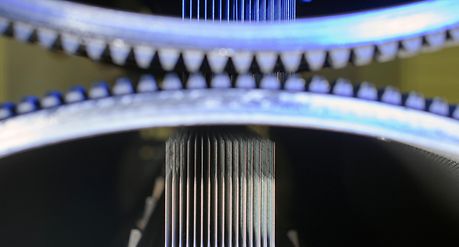

With the upgrade and re-design of the technical center, among others, also the brand new ANDRITZ PA.3000 cylindric pre-needleloom and the web optimization system ProWin.

The latest addition in the technical center for needlepunch is the ANDRITZ XPro™ crosslapper, a high-speed crosslapper, dedicated to needlepunhc lines as well as for spunlace configurations.

Technical Center Needlepunch main features:

- Complete Industrial-Scale pilot line

A full neXline needlepunch pilot line designed to replicate industrial-scale production for realistic trials. - Latest technology tntegration

Includes advanced components such as:- ANDRITZ eXcelle double card for uniform web formation

- ANDRITZ ProWin™ web optimization system for automatic weight correction

- ANDRITZ neXloom elliptica type DF-4 and orbital type 3000 needlelooms for versatile needling options

- ANDRITZ Battcruise system for batt layering precision

- High throughput capability

Handles short and long staple fibers with throughput exceeding 500 kg/h/m, ensuring efficiency for large-scale trials. - Integrated laboratory

On-site lab for testing nonwoven fabrics and validating product performance. - Digital solutions & simulation tools

Equipped with ANDRITZ Metris technologies for Industry 4.0, enabling real-time monitoring, recipe management, and predictive maintenance. Includes simulation tools like Matrix for investment decision support. - Versatile needling options

Needle from one or both sides using advanced needlelooms (e.g., A.50-R and A.50-RS), supporting a wide range of fabric specifications. - Comprehensive trial support

Customers can conduct R&D trials with their own fibers, supported by ANDRITZ process experts for optimization and efficiency improvements. - Training & knowledge sharing

Offers specialized training sessions on needlepunch processes, fiber-to-fabric transformation, and equipment operation. - Virtual tour availability

A digital walkthrough of the technical center for remote exploration and planning

Virtual Tour Technical Center

Make your own walkthrough & discover our Technical Center virtually

Video Needlepunch Technical Center Elbeuf

The latest ProWin™ automatic web weight correction system is available in the pilot line. ProWin™ works with a closed loop control system, coupled with the new ANDRITZ gauge, which handles machine-direction and cross-direction control. The pilot line also includes state-of-the-art opening and blending equipment as well as an automatic accumulator, slitter, and winder.

In addition, ANDRITZ also provides in its Technical Center the SDV-2+2 double-velour needleloom with fast offline or inline production (with great versatility), as well as improved loop quality and regularity, meeting the most demanding requirements of the automotive industry.

The Zeta drafter is designed for speeds of over 40 m/min and also has a very strong drafting capability, thus minimizing aspect distortion during fabric elongation. Furthermore, the A.50-R and A.50-RS needlelooms provide capabilities to needle from one side only or from both sides.

The pilot line also includes state-of-the-art opening and blending equipment as well as an automatic accumulator, slitter, and winder.

See more about the details about web optimization in the Needlepunch Technical Center with the unique ANDRITZ ProWin™ system.

Close up: ANDRITZ PA.3000 cylindric pre-needler

The unique ANDRITZ ProWin™ for web optimization

ANDRITZ SDV 2+2 double velour needleloom

ANDRITZ Zeta Drafter