Control center systems

The control center systems of ANDRITZ Hydro include 250 SCALA, SICAM, HYNET, video surveillance and power plant management.

The scalability of the systems allow the use at all automation levels - starting from turbine governor and unit control up to large control and dispatch centers.

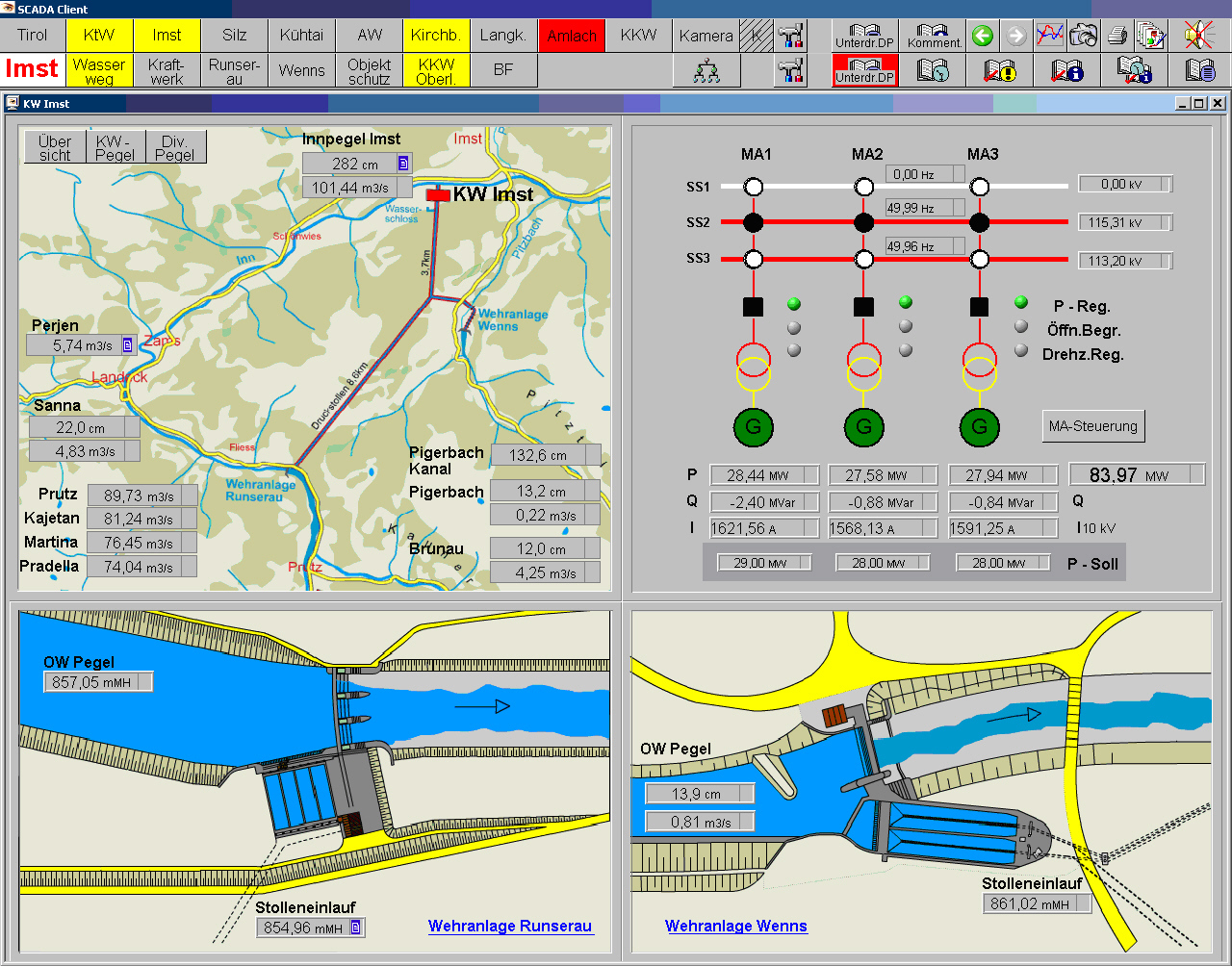

Control center with 250 SCALA

250 SCALA - central control rooms and generation dispatch centers

Due to its ability to process high telegram rates without time delay, 250 SCALA is also especially suitable for use in large control centers with a virtually unlimited amount of process data. For example, with a given data volume of 200,000 process signals, a continuous load of up to 3,000 telegrams/second can be processed. Database interfaces, remote desktop services, and the control of video walls are taken for granted. Specific concepts allow both operation as central servers and communication with various self-sustaining power plant servers, even with different program releases. Zooming and decluttering is supported as well as world views with an integrated navigator display.

Power plant control

The scalability of 250 SCALA starts with DIN rail PCs (without rotating parts) or standard PCs equipped with 1-4 screens and extends to large power plant control rooms with up to 100 workplaces. The integrated engineering concept with its centralized parameter administration allows the automatic distribution of process parameters and process views to the related control panels. The innovative human-machine interface offers efficient power plant operation.

In addition to the SCADA standards, many higher functions are available, such as topological coloring and interlocking, video surveillance, remote alerting via SMS to cell phones, monitoring of network infrastructure, as well as remote monitoring and diagnosis.

Turbine governor and gate control

With a data volume of 500 process signals, 250 SCALA is suitable here in its miniature design: as a tiny, compact 6" touch panel up to 15” touch panels. The general absence of rotating components allows use under harsh ambient conditions.

Automation System SICAM

The SICAM product family performs local control tasks based on the principle that the time-critical process automation tasks in a multi-hierarchical network are performed as close as possible to the process.

With the help of this automation system, we can fulfill the following tasks and more:

- Turbine Governor

- Control of auxiliary functions

- Start/Stop sequences

- Monitoring and control of external services

- Communication to remote stations and control centers

Balanced functionality enables the flexible combination of automation, telecontrol and communication tasks. Supplemented by the scalable performance and various redundancy configurations, optimum adaptation to the respective process requirements can be achieved.

The use of IEC 60870-5-101/103/104 standards ensures seamless addressing from source to acceptor. But the use of various third-party protocols also enables seamless integration into existing automation networks, thus ensuring long-term security of previous investments.

SICAM 1703 microprocessor

HYNET

HyNET forms the basis of secure communication inside and outside the power plant. Moreover, HyNET offers new and innovative solution processes.

The complexity of the fields of application, including the corresponding interfacing, inevitably results in a rapid increase in the danger of unwanted system access or malware contamination. Only a consistent security concept can align flexibility with the highest security requirements. A combination of security, availability and standardization is at the core of high-quality network engineering.

HyNET - the comprehensive, modular and custom-made network solution - has been designed to cater for these core topic areas.

Innovative solutions and a broad range of services can be achieved by a combination of experienced technical experts, defined processes and high-quality components. A comprehensive security concept is particularly important in network security.

Interlocking and interoperability of the security components lie at the heart of HyNET.

To meet such high system and network security requirements, the issue of security is considered comprehensively in HyNET and is put into practice as an integrated solution. The declared objective is a secure, scalable and manageable network which functions as a company-wide solution and also incorporates WLAN and VoIP.

Secure communication, efficiency and redundancy mean higher network and data security, lower operating costs, user satisfaction, and much more. HyNET combines a future-oriented environment and modern network technology for secure operation of power plants.

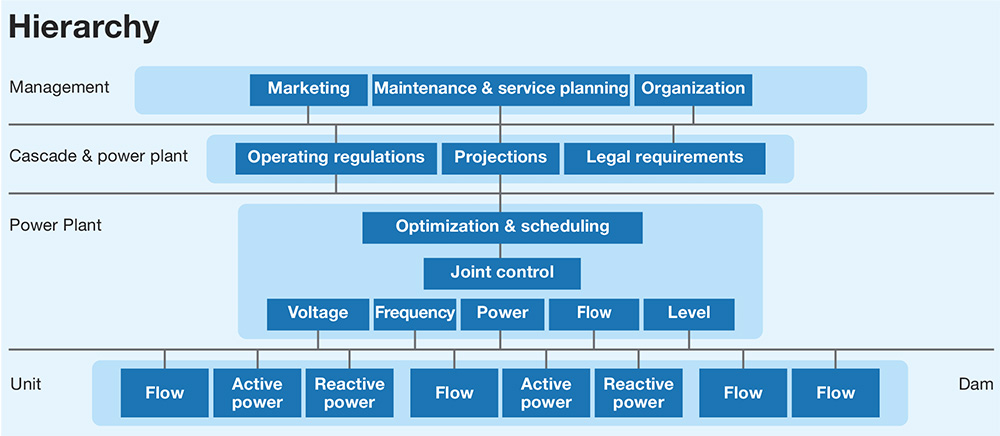

Neptun - power plant management

Power production must be maximized, while the costs should be reduced, both for single power plants as well as for power plant cascades. Modern power plant management systems perform these tasks very efficiently.

Beside the plant's operational requirements (e.g. maintenance cycle), the system has to take account of a number of external regulations, such as water management, contracts, and environmental regulations.

Due to the growing number of solar and wind power plants, optimum delivery of control energy (secondary control, tertiary control) is also gaining importance.

Production planning requires different modules for forecasting and optimization. Information has to be provided to other applications (e.g. commercial and administrative software tools) via standard interfaces.

All these different requirements require a modular overall concept.

Besides its main task - maximization of energy production - the system has to support the operators in various other operating conditions (e.g. normal operation, flood and disturbances). At the same time, the system has to contribute towards reducing operation and maintenance costs.

It must be possible to integrate the system easily into the power plant’s environment on the basis of the existing infrastructure.

Typical tasks of power plant management systems

Power plant control

- Head water level control

- Discharge control

- Power control

- Reactive power control

Authority and environmental regulations

- Downstream water flow limitation

- Filling and discharging gradients

- Level limitations

- Flood alert

Forecast

- Meteorological data (precipitation, temperature, snow depth, ...)

- Calculation of incoming water quantities

Optimization

- Energy production

- Reservoir utilization

- Swell operation of power plant cascades

- Production scheduling

- Secondary and tertiary control

Interfaces

- Equipment and maintenance database systems

- Commercial database systems

- Geographical information systems

- Office packages

Marketing and sales

- Internet (promotion)

- Intranet