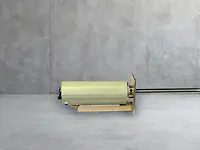

Wall-Eye HD

The Wall-Eye solid-state high-definition camera system delivers pristine, highly detailed images for coal, oil, or gas-fired boilers, pulp and paper recovery boilers, steel reheat furnaces, cement kilns, lime kilns, glass melt tanks, and negative pressure or balanced draft furnaces. The Wall-Eye system is ideal for viewing burners and flames in visible light areas of a boiler, furnace or kiln. A wide field-of-view allows you to see more of the boiler or furnace interior. Fixed and portable versions are available.

Features and benefits

- High-resolution 1/3 in. format optical probe capable of withstanding in excess of 593˚C (1100F)

- Special filter with enhanced sensitivity for low- or high-temperature applications

- 1080p full HD images

- Network connectivity (RJ-45)

- Digital recorder option with 4 or 8 POE ports for IP cameras

- Low compressed air consumption, 3 psig. @ 17 scfm.