Gauge level indicator aftermarket parts

We provide quality replacement parts for a wide range of gauge and level indicators. We also provide sight glass, covers and bolts for most of the Diamond Power legacy products.

Level probe and column

The Diamond Power® Series II level probe and column from are designed for steam/water level measurements using conductivity-type electronic level detection systems. The probe and column can replace leaking probe gaskets, failed probes, and corroded columns with superior technology, which is fully compatible with any existing electronic systems. The use of a junction box that is pre-wired to the probes makes installation simple.

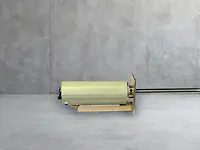

DP5500 ball check valve & DP5501 flow restrictor

The Diamond Power® Series II ball check valve and flow restrictor are designed to be used with visual level gauges to prevent excessive discharge from the gauge in case of glass failure. The ball check valve is installed on the lower gauge connection and the flow restrictor orifice is installed on the upper gauge connection. The ball check valve and flow restrictor are available in a number of mounting configurations.

Level gauge isolation valves

We offer a variety of high-quality Series II valves designed for visual level gauge isolation. All valves are forged steel and constructed to meet the rigorous demands of high-pressure steam boiler service.

High pressure ported boiler level gauge repair kits

The Diamond Power® Series II ported boiler level gauge repair kit is configured to fit Diamond Power level gauge designs. All repair kits use high quality material and are rated for 3000 psi (21 MPa) saturated steam service.