Benefits of Diamonized feed tubes

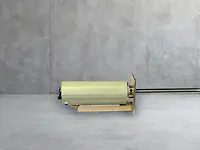

An upgrade to Diamonized feed tubes can prevent costly outages and improve boiler reliability. The Diamonized surface is 20% harder than a typical chrome-plated feed tube, yet it expands and contracts with the base metal, so it won’t crack under heat stress.

Extended feed tube and packing life: Durability of hardened material avoids the need for replacement due to peeling or cracking.

Reduced maintenance time and costs: Fewer packing replacements and less frequent repacking maintenance. A customer operating 60 retractable sootblowers reported feed tube packing and maintenance expenses were reduced by approximately 40,000 USD annually.

Better performance, improved efficiency: Minor leaks can result in steam losses of up to 90 kg/hr (200 lb/hr), safety hazards, shortened life of sootblower components, and accelerated gear rack and track wear.

Ready to extend your sootblower’s service life? Contact us for more information on Diamonized feed tubes or to discuss how an upgrade can integrate with your existing sootblowers.