Key functions of these sensors includes:

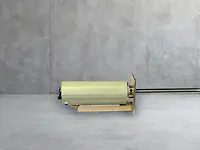

Since packing will be your only maintenance item, the PowerTrain carriage also cuts lubrication-related costs. There’s never a need for lubrication maintenance because the carriage features self-lubricated bearings; at-assembly, lifetime gear-side lubrication; and low-friction, dry-film lubrication on the hub chamber’s gear set. Also, since there is no need to add lubricant, there’s never a housekeeping issue.

Protecting furnace tube walls from excessive thermal shock (prevent accelerated tube wall cracking during water cleaning)

Adapting water flow and impact speed in Diamond Power Hydrojet furnace cleaning systems to current conditions

Measuring furnace wall heat transfer and regional temperatures for intelligent sootblowing goals and cleaning adjustments

Providing real-time data on furnace slagging conditions to enhance boiler reliability, availability and longevity

A design that allows the system to remain operational should one or two of the four thermocouples fail.

We have supplied over 6,000 Diamond Power heat transfer sensors worldwide in power generation utilities and other facilities, with some plants reporting 13+ years of reliable performance. These heat transfer sensors (often referred to as heat flux sensors) have been designed, engineered, and proven to last in harsh boiler environments. They are integral components in both water cleaning and intelligent sootblowing systems.