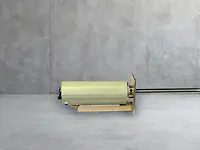

We developed a solution to maintain constant concentric packing load to assure a tight seal at all times. A high-strength wave spring inside the gland continuously presses the packing against the feed tube. This spring automatically compensates for any movement or wear during the sootblower’s operating cycle, keeping the seal tight in all conditions. It even compensates for packing wear.

Our live-loaded sootblower feed tube packing (i.e., a spring-loaded packing gland) design provides concentric loading without requiring torque setting of gland nuts and springs. The corrosion-resistant, solid-ring graphite foil packing is offered for the live-loaded gland to provide superior service. It is a flexible, all-graphite ribbon foil packing containing corrosion inhibitors, with no resin binders or organic fillers. It features high-density, conical ring-style packing, pre-formed to dimensions and configuration with interlocking construction for maximum strength.