USA, Old Hickory

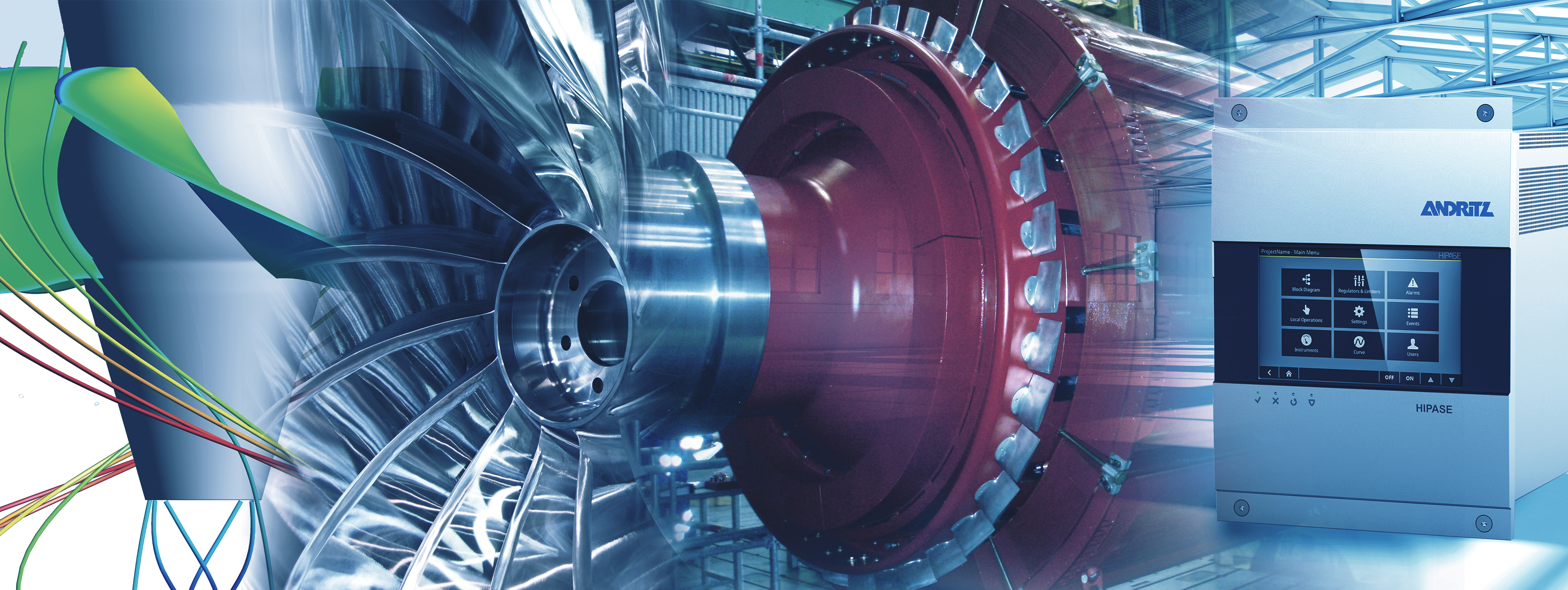

Rehabilitation and modernization of hydropower plants

Innovative modernization measures and state-of-the-art technologies increase profitability and extend the lifespan of your hydropower asset.

Benefits of our solution-oriented rehabilitation or upgrading concepts include

- Increasing annual production

- Extending lifetime of hydro assets

- Meeting modern market requirements

- Long-term optimization of assets.

Increasing annual production

The efficiency of turbines and generators has significantly increased over the last few decades. As a result, refurbishments to upgrade a plant’s performance are possible and highly cost-effective. Depending on the circumstances, an upgrade of a 40-year-old turbine runner can offer up to 5% more efficiency and an even bigger increase in terms of annual energy production. The overall efficiency of a hydropower plant can be optimized using digital controllers, for example.

Extending lifetime of hydro assets

As hydro equipment ages, wear and tear affects the plant efficiency. Aging is accelerated by certain plant operational regimes such as start-stop cycles, abrasion due to large volumes of suspended solids like silt, and corrosion. All have an impact on the service life.

Components related to consumer market products and/or automation and control systems typically need to be replaced first. High voltage electrical components such as cables, substations, and transformers, have a longer lifetime. Meanwhile, mechanical aging is a very slow process but nonetheless does affect the stationary parts of a turbine and generator, as well as structural elements like penstocks.

Meeting modern market requirements

Today, many hydropower plants are being challenged by more frequent start-stop cycles, operating at very low part loads and as spinning reserve, or as fast response capacity, for example to stabilize the transmission grid. Typically such installed equipment is aging much faster than originally envisaged because it was not designed for the demands of the modern grid.

Long-term optimization of assets

Maintenance of the electro-mechanical equipment is key to the long operational lifespan of a hydropower asset. The profitability and long-term value of a hydropower plant is significantly impacted by the quality of the ren-dered services. To fulfill value requirements and return on investment, remote assistance, emergency troubleshoot-ing and preventive, corrective and predictive mainte-nance are necessary. ANDRITZ services can range from continuous monitoring of relevant key performance indicators (KPIs) to adaptive operational optimization of multiple units and power plants.

Products, system and service portfolio for rehabilitation of your hydropower plant

ANDRITZ‘s global service and rehabilitation teams develop the necessary solutions to achieve maximum customer benefit and return on investment, based upon energy market developments, customer goals and plant conditions.

The services are ranging from hydro-mechanical scope, to electro-mechanical scope and lifetime services as well as life cycle and risk analysis. Operation and maintenance, but also digitalization are also part of our hydropower services.

Our systematic "Three-Phase-Approach" for tailor-made solutions

Modernization of a hydropower plant is an extremely complex issue. Aging of the various plant components and systems depends on operational, environmental and ambient conditions. Based on well over a century of hydropower experience, ANDRITZ has developed a structured process for assessing and modernizing hydropower plants in the most economical way. This systematic approach ensures tailor-made solutions that guarantee the maximum benefit for asset owners and operators.

Diagnosis

Our approach is based on a profound understanding of our customers’ machinery together with individual inspection and specific repair needs. All the required data, parameters and measurement results are registered, thoroughly assessed, and evaluated during this phase. This forms the basis for design evaluations.

Analysis

During this phase, our engineers focus on root cause analysis using modern in-house calculation tools for hydraulic and electro-mechanical design, as well as thermal distribution. The calculation results are validated with measurements and operational data coupled with the comprehensive design knowledge of ANDRITZ engineers.

Knowing the root cause is the basis for the design of unique solutions matching the specific hydro turbine and generator and avoiding a repeat of the same issue.

Therapy

We develop suitable scenarios to address the root cause of machine failures. These scenarios are evaluated and finally the most appropriate, feasible and economic solution is selected by the customer. The selected solution may also include conducting temporary repairs to keep the equipment in operation until a planned outage is possible in order for the final repair to take place. This reduces downtime and the related costs to a minimum for optimized life cycle costs