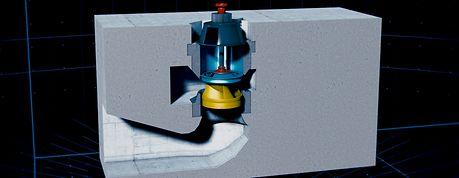

The tasks required to control a pump assembly can vary depending on the application. Generally, they not only include maintaining a specific output, but also optimum use of the pumps concerned in order to ensure the longest possible plant operating time. That is by no means easy.

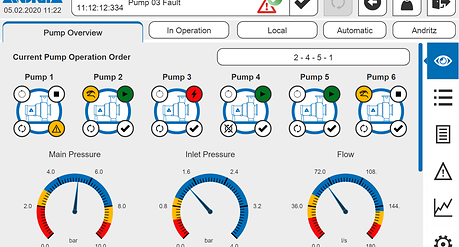

With the ANDRITZ Pump Controller (APC), ANDRITZ, however, offers a flexible control system for up to six pumps of different sizes and output that are interconnected to form a complete assembly. Due to its special configuration, the operator can run the plant without expert assistance, and more pumps can be added to the standard number at any time.