They say you can’t re-invent the wheel, but it seems that ANDRITZ has done just that with its PrimeDry Steel Yankee. The Yankee is even the shape of a wheel …

Yankee service - steel and cast

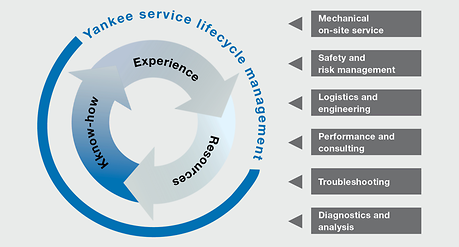

The ANDRITZ lifecycle management service for steel and cast Yankees offers comprehensive service tools to extend the Yankee’s lifetime and to improve its runnability and performance.

Audits

Lifecycle management

The ANDRITZ lifecycle management service for steel and cast Yankees – no matter if tissue, paper, MG-paper or tobacco; no matter what brand, no matter if old or new. The lifecycle management looks after your Yankee throughout its entire life span with on-site service and assembly, PrimeCoat Stratos coating technology, metallization work, and on-the-run measurements.

Mechanical on-site service

Apart from grinding services and exchange of spare parts, ANDRITZ offers leakage repairs, Yankee head testing and repairs, press NIP calibration, and doctor blade adjustment. And unlike other machine suppliers, ANDRITZ is capable of offering its own coating solution PrimeCoat Stratos. The thermal coating solution can be used for full-face coating edge and spot repair directly on site.

Safety and risk management

Annual or biannual checks are needed to confirm that the condition of the Yankee is in compliance with the pressure vessel safety regulations and other global standards (e.g. by insurance companies). Furthermore, an acoustic measurement can identify cracks independently on a steel or cast Yankee, provided if there is any serious damage.

Logistics and engineering

Unique logistics and engineering concepts for rebuilds and new installations offer a way of making the impossible possible. Nowadays, there seem to be no limits regarding Yankee sizes in production,but transport restrictions limit manufacturers in their possibilities. ANDRITZ has accepted the challenge and, with the world’s largest steel Yankee (24 ft. in diameter, installed at Pöls PM3, Austria), it has proved that its logistics concept really pays off.

Performance and consulting

When analyzing measurement results, the capability of seeing the bigger picture, meaning the production system and mill as a whole, is of utmost importance. Thus, ANDRITZ does not give recommendations only for the Yankee, but for the whole drying system and highlights potential for energy savings (like the combination of steel Yankee and steam heated hood) and improved runnability.

Troubleshooting

In case of problems, the ANDRITZ experts are able to find solutions covering not only the mechanical side, but also control logic issues in the steam and condensate system as well as automation issues. In addition, the dewatering rate can be checked and compared with the designed optimum running conditions. As ANDRITZ covers the whole process, even runnability issues caused by coating chemicals, steam and condensate, chemical treatment, or doctor issues can be solved.

Diagnostics and analysis | On-The-Run measurement

OTR is a perfect diagnostic and analysis tool for obtaining a clear picture of the Yankee under production conditions. The main parameters in Yankee drying are temperature and the mechanical surface profile of the Yankee. We have developed a special device to measure both variables under all production conditions. With this device, we can ensure highly accurate measurement of the temperature profile and precise measurement of the Yankee surface topography. Conductive material like organic coating is not penetrated and has no influence on the distance readings.

Yankee lifecycle management

Yankee experts

With more than 100 steel and cast Yankees supplied and successfully put into operation worldwide, among them the largest steel Yankee in the world, ANDRITZ has proved its knowledge and experience in the field of Yankees.

At a glance

- ANDRITZ lifecycle management for steel and cast Yankees to improve machine’s efficiency and Yankee’s performance

- Solutions and support for upgrades and replacements, safety, production, and analysis (e.g. on the run measurements).

- More than just regular service – customized solutions for Yankees in its complete environment and service activities throughout the complete Yankee’s lifecycle

Safety and risk management