Types of Diamond Power boiler cleaning applications:

- Water cleaning technologies

- Furnace wall cleaning

- Retractable sootblowers

- Rotary sootblowers

- Air heater sootblowers

Frequently used across industries, Diamond Power® is the brand that has set the industry standard. Diamond Power sootblowers are engineered to keep your boiler systems clean, efficient, and reliable.

Designed for a wide range of applications, from utility boilers to recovery boilers in pulp and paper mills, our sootblowers use steam, air, or water to remove ash and slag buildup from heat transfer surfaces. This targeted boiler cleaning improves thermal efficiency, reduces fuel consumption, and helps prevent costly downtime. With intelligent controls, rugged construction, and customizable configurations, Diamond Power sootblowers are boiler cleaning equipment that deliver proven performance in even the harshest operating environments. Whether you're upgrading an existing system or designing a new one, our soot blower solutions help you maintain peak boiler performance with confidence. Read more below about our boiler cleaning applications, such as retractable sootblowers and specialty cleaning functions, and reach out to us for Diamond Power boiler cleaning, we are happy to help you!

Our Diamond Power sootblowers are boiler cleaning equipment engineered for reliability in demanding industrial environments. Among them is the world’s largest retractable sootblower capable of traveling up to 18.3 meters for deep, efficient cleaning.

The Diamond Power sootblowers are available for all boiler cleaning applications, including fully and partially retractable, wall blowers and water lances, SCR catalyst, air heaters, and other specialty cleaning functions.

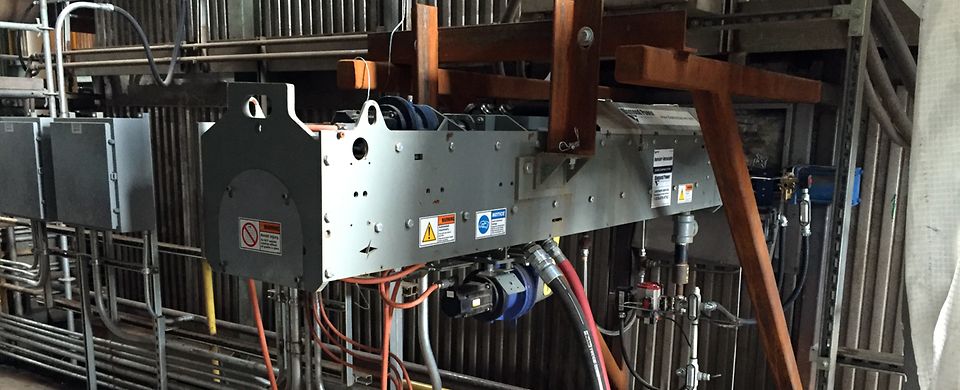

The HydroJet furnace water cleaning system is a rugged and reliable tool to clean any furnace surface within its line of sight from a mounting location up to 30.5 m (100 ft) away. Applications include division, furnace and wing walls. The HydroJet® furnace cleaning system is capable of accurately cleaning the entire width of the furnace. It controls thermal impact while cleaning previously hard-to-reach surfaces.

The uniquely designed HydroJet® retractable cleaning system extends the articulating nozzle into the furnace, vastly improving cleaning area coverage and effectiveness. Installation and maintenance are easy, and the full 180-degree rotation can help increase performance and boiler efficiency.

The Hydro Shower cleaning system is a robust fully automated solution for cleaning boiler walls of waste-to-energy (mass burn and refuse derived fuel) and biomass-fueled boilers.

Designed for use on furnace wall surfaces where slag deposits are not removed by steam or air supplied wall sootblowers.

The IR-3Z is a short travel, retracting sootblower, rotating 360 degrees and blowing through predetermined arc controlled by the valve trigger and cam.

A short retractable sootblower designed for a wide range of boiler applications.

We offer a full range of sootblowers, including longtravel retracable sooblowers for large utility boilers, wall-mounted sootblowers, for smaller utility boilers, wall-mounted sootblowers for smaller units, and more.

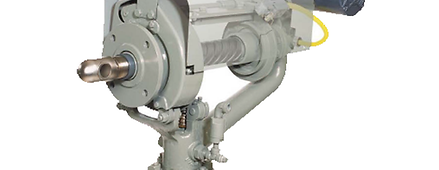

Diamond Power IK-525 retractable soot blower is the industry standard for online boiler cleaning needs.

The IK-4M conserves on expensive blowing media and reduces cycle cleaning time. Superior performance for a moderate investment.

The IK-530's single rack and pinion design offers an economical alternative for those seeking performance and durability. For boilers up to 22 meters in furnace width.

A rugged sootblower for the utility market that is designed for heavy duty cleaning jobs.

The IK-525SL is a retractable cleaner designed for applications in which the cleaner inserts and retracts the lance tube without rotation.

The IK-9M retractable sootblower is designed specifically for low maintenance, reliability, versatility and maximum cleaning performance.

A partially-retractable sootblower incorporating a traveling motor drive, transports a carriage along a supporting guide tube. A lance tube propels an element across the boiler.

The IK-525/545EL is designed for cleaning the heating surfaces of boilers and is used principally to remove slag and ash deposits from the superheater.

This proven, heavy-duty sootblower's construction is suitable for up to 24 operations per day (or more depending on steam conditions) and offers a logical balance between initial cost and lifetime maintenance.

The G9B is designed to remove ash deposits from tube surfaces.

The IK-AH air preheater sootblower cleans the heat transfer surface in regenerative air heaters with the medium of steam or air.

Engineered with the established IK-700 platform, this sootblower provides full and effective cleaning of SCRs and tubular air heaters. This application uses a non-rotating carriage and rake with nozzles specially designed for uniform coverage and effective cleaning.

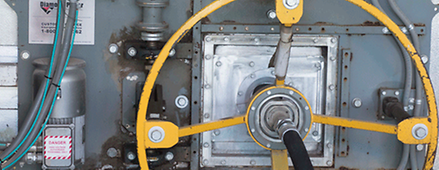

The IK-525DM provides the ability to steam (or air) clean high density air heater baskets while a unit is online and high pressure wash it while the unit is offline.

The IK-525DM3 Cleaner contains a traveling multi-nozzle element device designed to blow low pressure air or stream for the primary fluid and high pressure or low-pressure water for off-line cleaning.

Precisely designed nozzle head and rugged sootblower structure guarantees the positive cleaning without damaging the materials of the heat exchanger.

Maximize your plant’s reliability and extend equipment life with genuine OEM Diamond Power replacement parts. We offer a full range of components, servicing, and upgrade solutions for all current sootblowing systems, including those from other manufacturers, and even support legacy models no longer in production. Our expert-backed parts ensure seamless performance, long-term durability, and peace of mind.

Upgrades and replacement parts can help extend the life of your existing Diamond Power or other suppliers’ equipment. We offer complete equipment rebuilds and upgrades using OEM parts, complete with factory warranty. For sootblowing system upgrades, don’t hesitate to contact our Diamond Power team!

Through a dedicated team of professionals, we provide quality onsite services focused on the proper operation and maintenance of your boiler cleaning equipment and systems. Our complete turnkey services include all onsite installation, project management and technical oversight, including necessary labor, equipment, tools and consumables.