ANDRITZ recovery plant service experts work in close cooperation with you to improve the performance, stability, availability, and efficiency of your recovery boilers and auxiliary equipments.

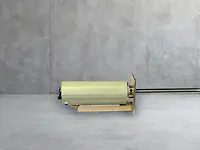

Titanium sootblowing boiler cleaning control systems

Flexible, intelligent sootblower control system for optimized boiler cleaning performance.

Titanium sootblowing controls represent a major advancement in boiler cleaning technology, providing an easy upgrade path from older systems to a smarter, data-driven platform that can be customized and expanded as plant needs change.

Whether you're upgrading an existing sootblower control system or starting fresh, Titanium control and Titanium Intelligent Sootblowing (ISB) options can help improve your boiler cleaning performance, regardless of boiler type or sootblower manufacturer.

Titanium is the latest evolution in Diamond Power® sootblowing controls. They are modernizing the trusted performance of our SentrySeries® systems and a long history in boiler cleaning with a flexible, intelligent platform built for today’s boiler demands.

Why choose Titanium?

Titanium is designed with your evolving needs in mind:

Flexible:

Installed in hundreds of boilers worldwide, Titanium offers a full range of configurations tailored to your specific application.

Titanium controls can be retrofitted on any boiler (Diamond Power or other makes), protecting your existing equipment investment while bringing it to modern standards.

Expandable: Modular design makes it easy to add new features and functions as your control needs evolve.

Fully supported: Backed by our expert team in controls, electrical systems, and sootblowing, leveraging deep industry experience.

Titanium Intelligent Sootblowing (ISB) uses real-time boiler performance data and heat transfer sensor feedback to direct cleaning exactly where and when it’s needed. It combines legacy intelligent sootblowing systems (ISB) into a powerful performance-driven system, which is flexible and easy to use. It can improve heat rate and unit efficiency, reduce steam consumption and tube erosion, and stabilize furnace temperatures.

| Titanium product | Applications | Features/benefits |

| Titanium advanced sootblower controls | Controls up to 300 sootblowers, including water cleaning devices |

|

| Titanium intelligent sootblowing |

|

|

| Sootblower controls for recovery boilers | Specialized option for pulp and paper recovery boilers |

|

In practice, these capabilities mean easier control of cleaning operations, fewer unexpected boiler issues, and more efficient use of steam and air for cleaning.

Contact us to learn how Titanium sootblowing controls can be tailored to your unit – whether you’re upgrading an existing system or installing a new one, we’ll help you boost performance while protecting your boiler.