Optimization, data analysis, augmented reality

WeValue series

Forming fabrics for specialty paper. High-tech ensures 100% reproducibility.

The challenge

Paper mills for specialty papers depend on controlled drainage, long lifetime, high dry content, running stability, clean run, prevention of fiber compression, uniform formation, effective filler/fines retention, as well as decreasing energy costs.

The solution

Filters, silk, decorative, or security papers: our forming fabrics are individually tailored for the most challenging applications with the highest quality demands. Our objective is to guarantee constant paper characteristics through perfect reproduction at a consistently high quality. Our key to success: The highest in precision and uniformity in every manufacturing step – starting with intelligent product design to the highest precision in weaving and on to final finishing. Control and strict monitoring of every individual manufacturing parameter are crucial. Process steps with especially high control potential are identified and constantly refined, enabling us to master the ultimate challenge: perfect reproduction of specialty papers to meet high demands.

We are able to perfect a complex production process that allows us to precisely balance the various parameters. Our coordinated thermofixing routines control the interaction of exactly defined temperature curves, the continuous build-up of traction, and the optimum time input – at an absolutely constant run speed. Our technologically balanced product designs offer tailored solutions for every type of paper machine and every grade of paper – for the highest demands and perfectly reproducible quality.

They ensure:

- homogeneous paper-side topography

- dimensional stability

- fixing of the weave architecture

WeValue PRIME – innovative solutions

- Newly developed design with added value for customers

- New energy-saving material compositions

- Containing Q-Line or E-Line monofilaments

- With more durable machine-side designs

- Finely structured paper side for optimum sheet quality

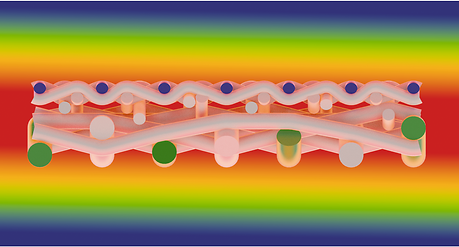

ANDRITZ picture

WeValue products at a glance

Features | WePrint RUN | WePrint PRIME |

| Wide range of different fabric designs and types (weft-bound and warp-bound, triple-layer SSB-designs) | x | x |

| Widely approved fabric designs for all special paper grades | x | x |

| No limitations regarding special paper types | x | |

| Higher retention values due to finer top side of fabric. | x | |

| Improved paper properties by improved surface planarity and more fiber support points | x | |

| Higher CMD fabric stability due the latest material developments (Q-Line) being applied | x |

Our services – in addition to our fabrics

- Dewatering measurements

- Analysis of fabric wear potential and calculation of remaining fabric life

- Caliper and tension profile over the total width of the fabric

- Stock jet velocity adjustments

- Evaluation of turbulence measurements

- Air permeability profiles

- Paper tests in the laboratory

- Layout assistance for forming table

- Troubleshooting and start-up service

- Fabric repairs

We document all measurements and provide a report on our analysis to each customer. This is part of our value-added approach to customer satisfaction – the best technology coupled with excellent service support.

WeValue PRIME technologies

Q-Line technology – a new generation of monofilaments

| Features | Benefits | Q-Line availability |

|

| Q-Line yarns are available for Prime ANDRITZ Kufferath SSB designs. |

QSB-Technology – a new, more effective way of bonding

| Features | Benefits | Q-Line availability |

Allows a significantly higher number of SSB binder points |

| QSB-Technology can be applied to fine and robust SSB |